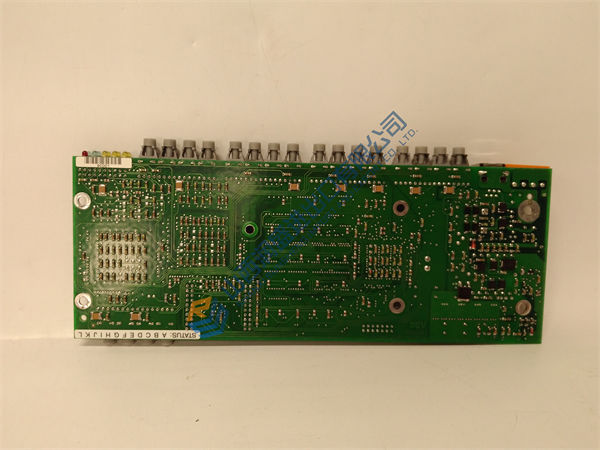

TRICONEX 3008 Product Description

- The TRICONEX 3008 is a Main Processor (MP) module within the TRICONEX Tricon Safety Instrumented System (SIS). It serves as the central processing unit, executing safety-critical control logic.

- Tricon systems are well-known for their Triple Modular Redundancy (TMR) architecture, which provides exceptional reliability and fault tolerance. The TRICONEX 3008 is crucial in this architecture, ensuring that the system continues to operate safely even if components fail.

- This module is designed for critical industrial applications that require the highest Safety Integrity Level (SIL), such as those found in the oil and gas, chemical processing, and power generation industries.

Key Technical Specifications

- Type: Main Processor (MP) Module

- Redundancy: Triple Modular Redundancy (TMR)

- Application: Safety Instrumented System (SIS)

- Memory: 16MB DRAM

- Primary Industries: Oil and gas, chemical processing, power generation, etc.

- Security Considerations:

- It is crucial to acknowledge that, according to sources like CISA (Cybersecurity and Infrastructure Security Agency) and CVE Details, certain firmware versions of the TRICONEX 3008 have known security vulnerabilities. This is a significant consideration for deployments in critical infrastructure.

Key Features and Benefits

- High Reliability: The TMR architecture guarantees continuous operation even if components fail.

- Fault Tolerance: Built-in diagnostics help to quickly detect and isolate faults, minimizing downtime.

- Safety Integrity: Designed to meet high SIL requirements, making it suitable for safety-critical applications.

- Core Processing: As the main processor, it plays a vital role in the overall safety control of the Tricon system.

Typical Applications

- Oil and Gas: Emergency shutdown systems (ESD), fire and gas (F&G) systems.

- Chemical Processing: Reactor control, pressure relief systems.

- Power Generation: Boiler control, turbine protection.

Competitive Considerations

- TRICONEX systems, including the 3008, offer superior reliability compared to many traditional PLC systems, especially in terms of TMR and SIL ratings.

- The Triconex 3008, as the main processer, is the core of the systems safety operations.

Selection Guidelines

- When selecting the 3008, consider:

- Application’s SIL requirements.

- System I/O capacity and communication needs.

- Environmental conditions (temperature, humidity, vibration).

- Firmware versions and associated security vulnerabilities.

- When deploying this equipment, ensure that the firmware is up to date and that all known security vulnerabilities have been patched.

Important Considerations

- Installation and maintenance should be performed by trained professionals.

- Adhere to manufacturer safety guidelines.

- Conduct regular system diagnostics and functional testing.

- Pay close attention to firmware security concerns.

- Consult official TRICONEX (Schneider Electric) documentation for precise specifications.