Description

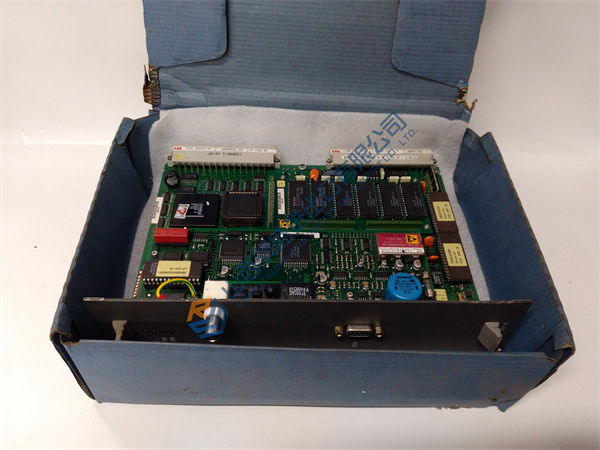

The ABB REX521GHHPSH07G is a versatile and reliable motor protection relay, part of ABB’s well-established REX 521 series. This dedicated relay provides comprehensive protection, control, and monitoring functionalities specifically designed for motors in a wide range of industrial applications, ensuring operational continuity and preventing costly motor damage.

Application Scenarios

Consider a critical pumping station in a water treatment plant, where the continuous operation of large electric motors is essential for maintaining water supply. An unexpected motor fault could lead to severe disruptions and impact public health. The ABB REX521GHHPSH07G acts as a vigilant protector for these vital motors. Installed in the motor control center, it continuously monitors key motor parameters such as current, voltage, and temperature. If it detects an overload, short circuit, earth fault, or other abnormal condition, the REX521GHHPSH07G swiftly trips the motor circuit breaker, preventing catastrophic damage to the motor and minimizing process downtime. Furthermore, the relay can provide valuable diagnostic information, aiding maintenance personnel in identifying the cause of the fault and implementing timely repairs, thus enhancing the overall reliability and efficiency of the water treatment plant’s operations.

Parameter

Main Parameters Value/Description Product Model REX521GHHPSH07G Manufacturer ABB Product Category Motor Protection Relay Rated Voltage System dependent Configurable to match various motor operating voltages. Rated Frequency 50/60 Hz Suitable for different power system frequencies. Current Inputs 3 x Phase Provides three-phase current measurement for comprehensive protection. Voltage Inputs 3 x Phase-to-Phase Monitors voltage levels for undervoltage and overvoltage protection. Protection Functions Overcurrent, short circuit, earth fault, thermal overload, undervoltage, overvoltage Comprehensive motor protection suite. Starting Curves Multiple Pre-defined and customizable curves to suit various motor starting characteristics. Binary Inputs Configurable For external commands and status monitoring. Binary Outputs Configurable For tripping, alarms, and control functions. Communication Protocol Optional Serial communication for remote monitoring and control. Mounting Type Flush mounting Standardized for easy panel installation.

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Thermal Overload Protection. The REX521GHHPSH07G incorporates sophisticated thermal models that accurately predict motor winding temperature based on the load and ambient conditions. This prevents motor overheating and damage, even under varying load cycles and intermittent overloads, extending the motor’s lifespan.

- Innovation Point 2: Comprehensive Fault Recording. The relay records detailed information about fault events, including current and voltage waveforms, tripping times, and fault types. This invaluable data aids in post-fault analysis, allowing engineers to understand the cause of the fault and optimize protection settings for improved system reliability.

- Innovation Point 3: Flexible Configuration and Parameterization. The REX521GHHPSH07G offers a wide range of configurable protection parameters and settings, allowing users to tailor the protection scheme precisely to the specific characteristics and requirements of the protected motor and the application.

- Innovation Point 4: Robust and Reliable Design. Built with high-quality components and adhering to stringent ABB standards, the REX521GHHPSH07G is designed for reliable operation in demanding industrial environments, ensuring long-term performance and minimizing maintenance requirements.

Application Cases and Industry Value

In a large manufacturing plant with numerous critical motor-driven machines, the ABB REX521GHHPSH07G relays are employed to protect motors powering pumps, compressors, and conveyors. By implementing these relays, the plant experienced a significant reduction in motor failures and associated production downtime. For instance, in one instance, the REX521GHHPSH07G detected a developing bearing fault in a critical pump motor by identifying an increase in motor current and temperature, allowing for proactive maintenance before a catastrophic failure occurred. This early detection saved the plant significant costs associated with emergency repairs and production losses. The detailed fault logs provided by the REX521GHHPSH07G also helped maintenance teams quickly diagnose and resolve motor issues, further improving operational efficiency.

Related Product Combination Solutions

- MSD Series Motor Starters: A range of motor starters from ABB that can be seamlessly integrated with the REX521GHHPSH07G for a complete motor control and protection solution.

- Emax 2 Series Circuit Breakers: ABB’s air circuit breakers that can be controlled and tripped by the REX521GHHPSH07G to provide reliable interruption of fault currents.

- ABB contactors: A wide selection of contactors from ABB suitable for motor starting and control applications, working in conjunction with the protection provided by the REX521GHHPSH07G.

- ABB current transformers: Instrument transformers that provide accurate current signals to the REX521GHHPSH07G for its protection functions.

- ABB voltage transformers: Instrument transformers that provide accurate voltage signals to the REX521GHHPSH07G for its monitoring and protection functions.

- ABB HMI panels: Human-Machine Interface panels from ABB that can be used to locally monitor the status and settings of the REX521GHHPSH07G.

- ABB Ability™ Condition Monitoring for motors: A digital solution that can be connected to the REX521GHHPSH07G to provide advanced analytics and predictive maintenance insights for the protected motor.

- ABB soft starters: Devices used to smoothly start and stop electric motors, which can be protected by the comprehensive protection features of the REX521GHHPSH07G.

Installation, Maintenance, and Full-Cycle Support

The ABB REX521GHHPSH07G is designed for straightforward flush mounting in standard industrial control panels. Its clearly marked terminals facilitate easy wiring. Commissioning involves configuring the protection parameters to match the specific motor and application requirements, typically done using dedicated software tools. The relay is built for reliable operation in industrial environments. Routine maintenance is minimal, primarily involving periodic checks of the relay’s status and connections. The self-supervision features of the REX521GHHPSH07G continuously monitor its internal health, providing alarms in case of any issues. Fault diagnostics are simplified by the detailed event and fault recording capabilities.

ABB provides comprehensive technical support for the REX521GHHPSH07G, including detailed product manuals, application notes, and software tools. Our global network of certified service engineers offers on-site support for installation, commissioning, and maintenance. We are committed to providing long-term support for our motor protection relays, ensuring the availability of spare parts and offering migration paths for future system upgrades.