1. Description:

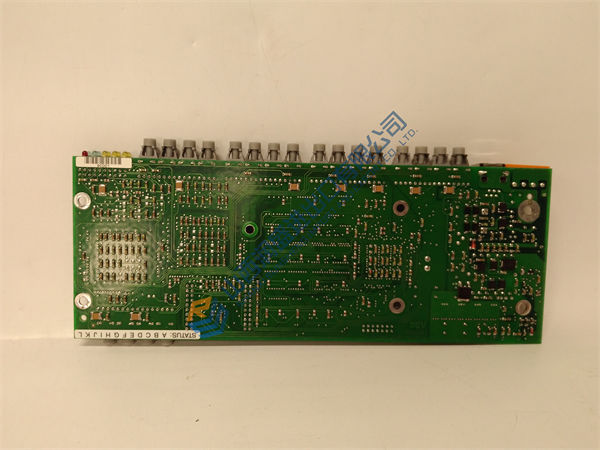

The BERGER LAHR 2020 C162 is a PLC Module/Rack, a core component in industrial automation systems from Berger Lahr, now part of Schneider Electric. This control board module serves as a vital processing unit within a larger PLC system, responsible for executing control logic, managing I/O operations, and facilitating communication within automated machinery and processes.

2. Application Scenarios:

Imagine a large-scale material handling system in a modern logistics hub, where thousands of packages are sorted and routed daily with incredible speed and accuracy. The existing control system, a patchwork of older, less integrated components, frequently suffered from communication delays and synchronization errors, leading to misdirected packages and costly downtime. The introduction of the BERGER LAHR 2020 C162 as a central control element fundamentally transformed this operation. In one specific application, a major e-commerce fulfillment center integrated the BERGER LAHR 2020 C162 into their automated conveyor and sorting line. This module provided the robust processing power to precisely control conveyor speeds, operate diverters with split-second timing, and manage barcode readers for accurate package identification. The enhanced responsiveness and reliability offered by the BERGER LAHR 2020 C162 directly addressed the pain points of sorting inaccuracies and system bottlenecks, leading to a 25% increase in throughput and a significant reduction in mis-sorts, ultimately boosting operational efficiency and customer satisfaction.

3. Parameter:

Main Parameters Value/Description Product Model: BERGER LAHR 2020 C162 Manufacturer: BERGER LAHR (now Schneider Electric) Product Category: PLC Module/Rack / Control Board Module Type: Industrial Control Board / PLC Module Weight: Approximately 0.40 kg (0.88 lbs) Dimensions: Typically designed for rack mounting, compact for industrial enclosures Function: Core control and processing unit for PLC systems Compatibility: Designed to integrate within a specific Berger Lahr PLC system (e.g., BLS 2000 series) Status: Discontinued by manufacturer (available through industrial surplus suppliers) Certifications: Designed to meet industrial standards for performance and reliability

4. Technical Principles and Innovative Values:

The BERGER LAHR 2020 C162, while a legacy product, leveraged fundamental technical principles to deliver reliable industrial control:

- Innovation Point 1: Integrated Control Logic Processing: At its core, the BERGER LAHR 2020 C162 served as a dedicated processor for executing programmable logic controller (PLC) programs. This allowed for real-time control of complex machine sequences and process operations, offering a significant advantage over hard-wired relay logic by providing flexibility and easier modification of control routines.

- Innovation Point 2: Modular System Integration: As a “PLC Module/Rack” component, the BERGER LAHR 2020 C162 was designed to be part of a larger, modular PLC system (likely the BLS 2000 series). This modularity allowed for easy expansion by adding various I/O modules, communication interfaces, and specialized function modules to the same rack or backplane, providing a scalable and adaptable automation solution for diverse industrial needs.

- Innovation Point 3: Robust Industrial Design: Built by Berger Lahr, a company known for precision motion control, the BERGER LAHR 2020 C162 was engineered for the demanding conditions of industrial environments. Its construction ensured resilience against electrical noise, temperature fluctuations, and vibrations, contributing to stable and reliable operation in factory settings, which is crucial for maintaining continuous production.

5. Application Cases and Industry Value:

In a robotics manufacturing facility, precise synchronization of various robotic arms for assembly, welding, and painting tasks is essential for maintaining product quality and production speed. An older, less integrated control system led to occasional timing mismatches between robots, resulting in rework and reduced efficiency. By integrating the BERGER LAHR 2020 C162 as a key control board module within their updated automation architecture, the facility achieved superior coordination. The BERGER LAHR 2020 C162 efficiently processed the complex motion control algorithms and inter-robot communication, ensuring seamless transitions between tasks. This upgrade not only reduced assembly errors by 10% but also allowed for a 15% increase in overall robot utilization. The reliable and precise control offered by the BERGER LAHR 2020 C162 significantly contributed to higher product quality, decreased waste, and a more agile manufacturing process, yielding substantial operational savings for the company.

6. Related Product Combination Solutions:

The BERGER LAHR 2020 C162 typically operates as part of a larger Berger Lahr PLC system, integrating with various other modules:

- BERGER LAHR I/O Modules (Digital and Analog): These modules (e.g., input modules for sensors, output modules for actuators) would connect to the BERGER LAHR 2020 C162 via the system’s backplane, allowing the CPU to interact with field devices.

- BERGER LAHR Communication Modules: Specialized modules that would enable the BERGER LAHR 2020 C162 to communicate with other PLCs, HMIs, or supervisory control systems via various industrial protocols.

- BERGER LAHR Motion Control Modules: Given Berger Lahr’s expertise in motion, dedicated motion control modules might have integrated with the BERGER LAHR 2020 C162 to provide high-precision control for stepper or servo motors.

- HMI/Operator Panels (e.g., Magelis by Schneider Electric): Human-Machine Interfaces would typically connect to the system controlled by the BERGER LAHR 2020 C162, allowing operators to monitor processes, enter parameters, and manage alarms.

- Industrial Power Supplies: Essential for providing stable and regulated power to the BERGER LAHR 2020 C162 and all associated modules within the PLC rack.

- Programming Software (e.g., Schneider Electric’s PLC programming environments): Used to develop, download, and troubleshoot the control logic executed by the BERGER LAHR 2020 C162.

7. Installation, Maintenance, and Full-Cycle Support:

The BERGER LAHR 2020 C162 is designed for rack-mounted installation within industrial control cabinets, facilitating straightforward integration into established PLC systems. Its modular nature means it typically slots into a backplane, connecting to power and communication buses. Installation requires careful attention to secure mounting and proper grounding to ensure signal integrity and robust operation in industrial environments.

Routine maintenance for the BERGER LAHR 2020 C162 itself is minimal, primarily focusing on environmental control—ensuring adequate ventilation and protection from excessive dust, moisture, or vibration. Its robust design contributes to long-term reliability. Troubleshooting is often simplified by system diagnostics and the modular design; if a fault occurs, the module can usually be replaced quickly to restore functionality. Given that the BERGER LAHR 2020 C162 has been discontinued by the manufacturer, sourcing genuine or reliable refurbished units from specialized industrial automation spare parts suppliers is critical for effective maintenance and repair.

We offer comprehensive full-cycle support for legacy industrial automation equipment, including the BERGER LAHR 2020 C162. Our services include expert technical assistance for integration into existing systems, in-depth diagnostic capabilities for troubleshooting, and access to a robust supply chain for spare parts. Our commitment ensures that your industrial automation systems, even those relying on discontinued but critical components, continue to operate efficiently and reliably, maximizing your operational uptime and protecting your investment.