The ABB PCS 6000 product family is a line of advanced medium voltage power converters primarily known for their high efficiency, reliability, and modularity in demanding applications. While the family encompasses solutions for various industrial sectors, its most prominent and well-documented application is in the renewable energy sector, particularly for large-scale wind turbines and grid stabilization.

Here’s a breakdown of the PCS 6000 product family:

Description:

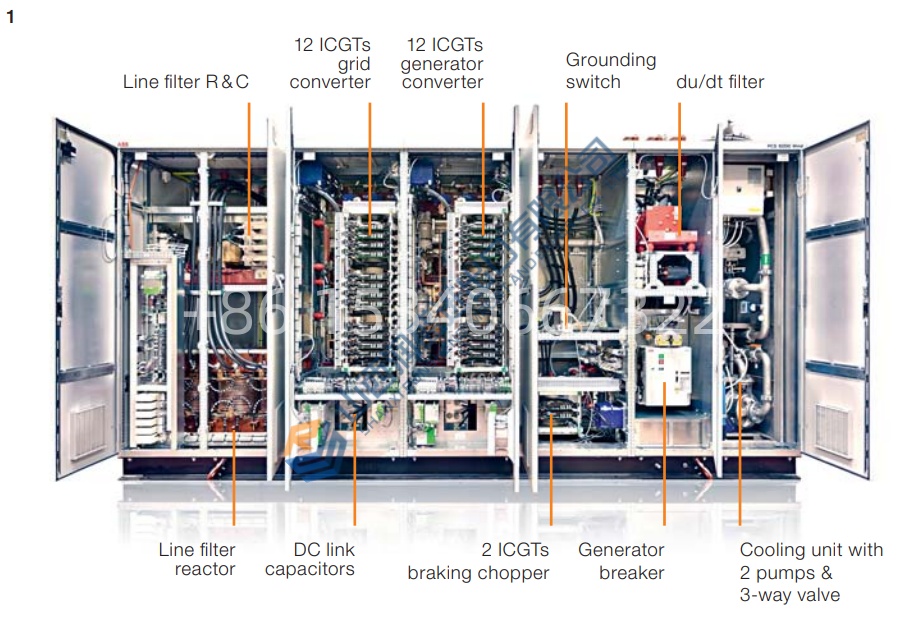

The ABB PCS 6000 is a modular, medium-voltage, full-power converter platform. It’s designed to interface between variable-speed generators (like those in wind turbines) or energy storage systems and the electrical grid, ensuring efficient power transfer and grid stability. A key feature is its utilization of advanced IGCT (Integrated Gate-Commutated Thyristor) technology, which provides high efficiency, low losses, and robust performance in high-power applications. The “full power” aspect means it converts 100% of the generated power, enabling optimal control and grid compliance.

Key Features & Benefits:

- High Efficiency: Typically boasts efficiency rates close to 98% at rated power, minimizing energy losses during conversion. This is largely due to the use of IGCT technology and optimized control algorithms.

- Modular and Compact Design: The PCS 6000 uses a modular “Power Electronic Building Block” (PEBB) concept. This allows for scalability, easy customization for specific power ranges (e.g., from 4 MW up to 15 MW, and even higher for some applications), simplified installation (can be tower-base or nacelle mounted), and faster maintenance through hot-swappable components.

- High Reliability & Durability: Designed with a low component count, robust construction, and often water-cooled closed-loop cooling systems. This ensures a long operational lifespan and high availability, crucial for remote and demanding environments like offshore wind farms. Its fuse-less design with intelligent protection further enhances reliability.

- Advanced Grid Code Compliance (Fault Ride-Through): A critical feature for modern grids. The PCS 6000 can maintain connection and provide grid support even during significant grid disturbances such as voltage sags (Low Voltage Ride-Through – LVRT) or swells (High Voltage Ride-Through – HVRT). This prevents costly disconnections and enhances overall grid stability.

- Dynamic Braking Chopper: Enables controlled shutdown and helps manage excess energy, providing overspeed and overvoltage protection for the system.

- Intelligent Control: Equipped with ABB’s high-performance AC 800PEC controller, allowing for sophisticated control algorithms (like Maximum Power Point Tracking for renewables), active and reactive power control, and seamless grid synchronization.

- Remote Monitoring & Diagnostics: Supports remote access and software tools for real-time performance monitoring, fault detection, and remote troubleshooting, reducing the need for on-site interventions.

- Power Quality Improvement: Can eliminate harmonics (e.g., below the 29th order) and contribute to dynamic voltage stabilization and reactive power compensation, improving overall grid power quality.

Main Application Areas:

The PCS 6000 product family is highly versatile, but its primary applications include:

- Renewable Energy Generation:

- Large-scale Wind Turbines: This is the most prominent application, especially for offshore and large onshore wind farms (e.g., 5 MW, 9 MW, 12 MW, and even 13 MW turbines). The PCS 6000 converts the variable frequency output from the wind turbine generator into stable grid-compliant power, with robust fault ride-through capabilities to meet strict grid codes.

- Solar Parks (Utility-Scale): Used in large solar power plants to efficiently convert DC power from solar arrays into AC power for grid injection, similar to its role in wind power.

- Tidal and Wave Energy Systems: Applicable to other ocean energy generation projects for stable grid connection.

- Grid Support and Power Quality:

- STATCOM (Static Synchronous Compensator) Solutions: PCS 6000-based STATCOMs are used for dynamic voltage stabilization, voltage balancing of asymmetrical loads, mitigating voltage flicker (e.g., from electric arc furnaces), and active harmonic filtering in utilities and heavy industries. They provide dynamic reactive power compensation.

- Static Frequency Converters (SFC): For converting electricity from one frequency to another, crucial for interconnecting different power grids or specialized industrial loads.

- Heavy Industrial Applications:

- Mine Hoists & Conveyor Systems: Providing precise speed and torque control for large motors in demanding mining operations.

- High-Power Centrifugal Compressors: Ensuring efficient and reliable operation of large compressors.

- Rolling Mill Main Drives: Offering robust control for heavy machinery in steel and other metal industries.

- Marine Propulsion Drives: For high-power marine applications.

- Electric Arc Furnaces: Mitigating flicker and improving power quality.

- Railway Electrification: Providing stable and controlled power for traction systems.

Key Components within the PCS 6000 Family:

While a “family” rather than a single component, some notable elements associated with the PCS 6000 include:

- Converter Modules/Units: The core power electronic blocks that perform the actual power conversion. These often utilize IGCTs.

- Grid Breaker Units (e.g., GBU72 / 3BHE055094R0002): Integrated or closely associated protection modules that ensure rapid fault current interruption on the grid side.

- AC 800PEC Controller: The advanced control platform that governs the operation of the entire converter system.

- Cooling Systems: Typically integrated closed-loop water-cooling units essential for managing heat dissipation from high-power semiconductors.

The ABB PCS 6000 family is recognized for its robust, flexible, and high-performance solutions, making it a preferred choice for large-scale power conversion and grid integration in the renewable energy and heavy industrial sectors.