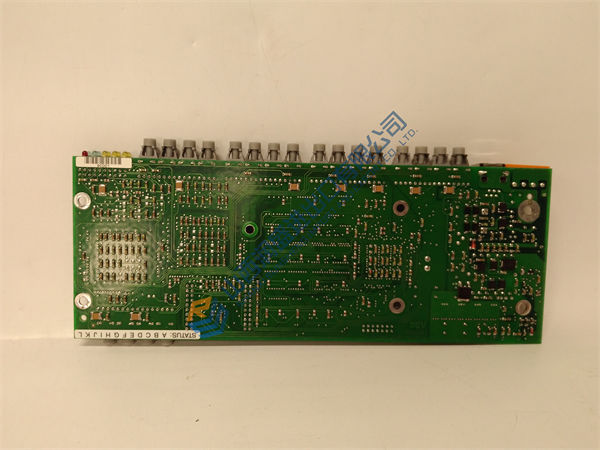

Product Description for Pacific Scientific 6435-001-K-N

Description: The 6435-001-K-N is a microstepping drive from Pacific Scientific, designed for precision motion control applications. This drive module is a comprehensive solution, integrating a power supply and oscillator with a high-performance stepping motor drive card, making it a powerful and economical choice for a wide range of industrial automation tasks.

Application Scenarios: Imagine a high-speed pick-and-place machine in a semiconductor manufacturing facility. The machine’s stepper motors need to move with exceptional speed and accuracy to handle delicate silicon wafers. A common challenge with standard stepper systems is mid-range speed instability, which can cause vibrations, lost steps, and ultimately, damaged products. A leading equipment manufacturer solved this by implementing the Pacific Scientific 6435-001-K-N drives. Its patented Digital Electronic Damping technology actively counteracts this instability, ensuring smooth, high-torque operation across the entire speed range. This allowed the machine to operate at higher speeds without sacrificing precision, increasing throughput by 20% and significantly reducing the rate of damaged wafers. The 6435-001-K-N proved to be the key to unlocking both speed and reliability in a mission-critical application.

Parameter:

Main Parameters Value/Description Product Model: 6435-001-K-N Manufacturer: PACIFIC SCIENTIFIC (now a brand of Kollmorgen) Product Category: Stepper Motor Drive Input Voltage: 120/240 VAC, 50/60 Hz (switch selectable), offering global adaptability. Output Current: Adjustable from 0.625 A to 5 A RMS, providing flexibility to match various motor sizes. Peak Output Current: 7.1 A peak (microstepping), delivering the power needed for dynamic movements. Output Voltage: 66 VDC, suitable for powering compatible motors and secondary drives. Drive Type: Patented 4-phase bipolar chopper, ensuring precise current regulation and low ripple. Microstepping Resolution: Up to 51,200 steps per revolution, for exceptionally smooth and quiet operation. Dimensions: 2.25″ W x 6.25″ H x 10.0″ D (5.7 cm x 15.9 cm x 25.4 cm), a compact footprint for panel space efficiency. Operating Temperature: 0°C to 50°C, suitable for typical industrial control environments.

Technical Principles and Innovative Values:

- Innovation Point 1: Digital Electronic Damping™: A key differentiator of the 6435-001-K-N is its patented Digital Electronic Damping technology. This intelligent feature actively mitigates the mid-range speed instability that plagues traditional stepper motor systems. By advancing or delaying the switching of the output current, it effectively suppresses resonance, resulting in smoother motion and higher torque across a broader speed range. This innovation allows for higher machine speeds and improved positioning accuracy.

- Innovation Point 2: Integrated and Efficient Design: The 6435-001-K-N stands out by combining a high-performance microstepping drive with an integral AC power supply and oscillator. This all-in-one design simplifies system architecture, reduces wiring complexity, and saves valuable panel space. The inclusion of an adjustable current control and switch-selectable settings offers unparalleled ease of use and customization for specific application needs.

- Innovation Point 3: High-Resolution Microstepping: The drive’s ability to achieve up to 51,200 steps per revolution provides superior resolution, leading to exceptionally smooth and quiet motor operation. This high-resolution control is critical in applications where precise, incremental movements are required, such as in optics, laboratory automation, or printing equipment. The patented 4-phase bipolar chopper drive ensures that this microstepping is executed with minimal ripple current, further enhancing performance.

Application Cases and Industry Value:

A high-volume packaging line was experiencing frequent jams due to inconsistent conveyor positioning. The stepper motor driving the indexing conveyor would often “overshoot” its target, requiring manual intervention and causing production delays. After replacing the legacy drive with the PACIFIC SCIENTIFIC 6435-001-K-N, the issue was completely resolved. The drive’s precise microstepping and damping capabilities enabled the conveyor to start and stop with pinpoint accuracy. The smooth acceleration and deceleration curves, configured easily with the drive’s internal settings, eliminated jarring movements that had previously caused products to shift. This change not only improved the overall efficiency of the packaging line but also reduced maintenance costs associated with component wear and tear.

Related Product Combination Solutions:

To build a complete motion control solution with the PACIFIC SCIENTIFIC 6435-001-K-N, consider integrating the following products:

- Pacific Scientific 6410 Drive: This is the core stepper drive component of the 6435-001-K-N. It can be used as a separate, DC-powered drive for multi-axis systems, powered by the 6435-001-K-N‘s auxiliary DC output.

- Pacific Scientific 6440 Stepper Drive/Indexer: For applications requiring more advanced programming and communication capabilities, the 6440 series offers an integrated indexer, making it a powerful companion for the 6435-001-K-N in complex motion sequences.

- Pacific Scientific NEMA 23/34 Stepper Motors: The 6435-001-K-N is designed to pair seamlessly with Pacific Scientific’s own line of stepper motors, ensuring optimal performance and compatibility.

- PACIFIC SCIENTIFIC 6430 Series: A closely related family of drives, the 6430 series is an alternative that also features an integral power supply, offering a similar set of high-performance features for different voltage or current requirements.

- Pacific Scientific SC724A-001 Servo Motor Control: For applications that may transition to higher dynamic demands, this servo control unit from Pacific Scientific is a suitable upgrade path, offering greater speed and torque capabilities.

Installation, Maintenance, and Full-Cycle Support:

The PACIFIC SCIENTIFIC 6435-001-K-N is engineered for straightforward installation and dependable, long-term operation. Its compact design and clear terminal markings simplify the wiring process, reducing installation time and the potential for errors. The drive’s switch-selectable settings for current and microstepping allow for easy configuration without the need for complex software, enabling quick commissioning and fine-tuning.

Maintenance requirements are minimal due to its robust, solid-state construction. The drive is built with fault protection features, including line-to-line shorts and under-voltage protection, to safeguard the unit and the motor from potential damage. Troubleshooting is facilitated by on-board diagnostics, making it easier to identify and address issues promptly. While this product is now a discontinued legacy model, our technical support and service commitment ensure you have access to expert knowledge, repair services, and sourcing for spare parts to keep your systems running. We provide support for the entire lifecycle of the product.

Contact us for a customized solution and to learn how the 6435-001-K-N can enhance your industrial automation system.