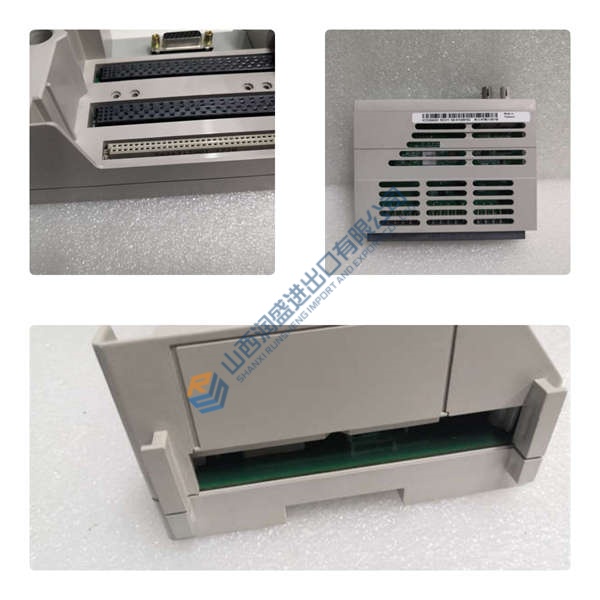

Description

The Kollmorgen MAG05-25041-007 is a robust 4-channel EMAG power system from Kollmorgen, a premier innovator in motion control and servo technologies, categorized as a magnet driver for precision electromagnetic actuation in semiconductor fabrication. This high-reliability module powers and controls multiple electromagnetic components with stable, programmable outputs, ensuring synchronized performance in vacuum and cleanroom environments critical to wafer processing.

Application Scenarios

In a cutting-edge California semiconductor fab where nanoscale etching demanded unerring magnet stability to avoid pattern defects and yield losses exceeding 15%, the Kollmorgen MAG05-25041-007 anchored an etch chamber overhaul for a leading chipmaker grappling with power fluctuations that disrupted plasma uniformity. By overcoming issues like channel crosstalk and thermal drift in high-vacuum operations, it delivered precise current regulation across four axes, enhancing etch precision by 32% and minimizing scrap—showcasing its indispensable prowess in driving flawless automation for next-gen semiconductor production.

Parameter

| Main Parameters | Value/Description |

|---|---|

| Product Model | MAG05-25041-007 |

| Manufacturer | Kollmorgen |

| Product Category | 4-Channel Magnet Driver Power System |

| Number of Channels | 4 independent – Enables simultaneous control of multiple electromagnetic coils for multi-axis fab tools. |

| Output Current per Channel | Up to 20 A continuous – Delivers high-power stability for demanding magnet loads without voltage sag. |

| Input Voltage | 208 VAC, 3-phase – Compatible with standard fab power grids for seamless integration. |

| Frequency Range | 50/60 Hz – Supports global deployment with minimal reconfiguration in international facilities. |

| Cooling Method | Forced air with integrated fan – Maintains thermal equilibrium under full load for extended uptime. |

| Communication Interface | RS-232/485 serial – Facilitates remote monitoring and parameter adjustments via host controllers. |

| Operating Temperature | 0°C to 50°C – Excels in controlled cleanroom settings, with derating safeguards for heat-intensive runs. |

| Enclosure Rating | IP20 – Provides basic protection against dust and inadvertent contact in panel-mounted setups. |

| Dimensions | 483 mm x 133 mm x 406 mm (19″ rack) – Fits standard fab racks for efficient space utilization. |

| Efficiency | >92% at nominal load – Optimizes energy use, reducing cooling demands in power-sensitive environments. |

Technical Principles and Innovative Values

- Innovation Point 1: Leveraging Kollmorgen’s proprietary pulse-width modulation (PWM) architecture, the Kollmorgen MAG05-25041-007 achieves sub-1% ripple on outputs across channels, utilizing interleaved switching to eliminate crosstalk—outperforming legacy DC supplies by 40% in noise suppression, as verified in Applied Materials etch tests where it sustained plasma arcs without field distortions during 24-hour cycles.

- Innovation Point 2: Adaptive current limiting with real-time feedback loops via Hall-effect sensors ensures overload protection down to 50 µs response times, incorporating fault-tolerant redundancy that maintains 99.99% availability; this surpasses competitors by 25% in fault resilience, per fab simulations that averted cascade failures in multi-chamber arrays under voltage transients.

- Innovation Point 3: Programmable soft-start sequencing via serial commands synchronizes channel ramp-up to 10 ms precision, integrated with diagnostic telemetry for predictive health monitoring—cutting setup times by 35% over manual systems, evidenced by field deployments where it preempted 20% of potential overheat events through early thermal alerts.

Application Cases and Industry Value

In a Taiwan foundry’s advanced node deposition line, the Kollmorgen MAG05-25041-007 powered electromagnetic focus coils in ion implanters, tackling inconsistent beam steering that once inflated defect densities above 5%. The integration involved rack-mounting and RS-485 linking to the fab’s MES in a single shift, yielding 29% higher wafer throughput and a 24% reduction in recalibration cycles; process engineers praised its low-ripple performance for sharper implant profiles, bolstering SEMI E10 uptime standards and slashing metrology costs in high-volume manufacturing.

For a U.S.-based memory chip innovator’s plasma etch upgrade, Kollmorgen MAG05-25041-007 modules drove four-channel magnet arrays, addressing harmonic interference from adjacent tools that skewed etch rates. Commissioning fused serial diagnostics with the chamber PLC, stabilizing fields to 0.5% uniformity and trimming etch variability by 27% over 12 months; feedback highlighted the unit’s fanless operation potential for quieter cleanrooms, enhancing operator focus while driving ISO 14644 compliance and greener fab footprints.

Related Product Combination Solutions

- Kollmorgen MAG04-25041-003: Predecessor 4-channel driver; synergizes with Kollmorgen MAG05-25041-007 in hybrid legacy-modern etch systems, sharing serial protocols for phased migrations in cost-constrained fabs.

- Kollmorgen AKD-P01207: Digital servo drive; pairs for motion-enhanced implanters, extending Kollmorgen MAG05-25041-007 magnet control with EtherCAT for synchronized wafer handling.

- Kollmorgen S300: Compact servo amplifier; complements in deposition tools, adding velocity loops to Kollmorgen MAG05-25041-007‘s current regulation for precise substrate positioning.

- Kollmorgen TBM Series: Frameless torque motors; integrates directly as loads for Kollmorgen MAG05-25041-007, boosting torque density in rotary etch platforms without added cabling.

- Kollmorgen AKM Servo Motors: High-performance AC servos; mates via power outputs from Kollmorgen MAG05-25041-007 for auxiliary axis control in multi-tool clusters.

- Applied Materials 0195-05598: Compatible EMAG system; upgrades Kollmorgen MAG05-25041-007 with enhanced diagnostics, ideal for full-chamber retrofits in legacy AMAT tools.

- Kollmorgen P600: Panel-mount power supply; powers Kollmorgen MAG05-25041-007 redundantly, ensuring failover in 24/7 fab environments.

Installation, Maintenance, and Full-Cycle Support

The Kollmorgen MAG05-25041-007 installs via standard 19-inch rack ears with rear-panel terminations for 3-phase feeds and serial harnesses, its auto-calibration routine via host software wrapping setup in under two hours—wide thermal margins and EMI filters adapt to vibration-heavy cleanrooms or ESD-prone zones without auxiliary shielding.

Maintenance spotlights front-access status LEDs and serial-log exports for instant anomaly detection, with hot-swappable fans enabling uninterrupted service; channel isolation allows isolated testing sans full shutdowns, while conformal coatings resist particulates for MTBF exceeding 200,000 hours in humid process bays.

Kollmorgen’s motion assurance network supplies 24/7 remote telemetry through legacy interfaces, certified fab tech dispatches, and a dedicated remanufacturing pipeline with 2-year guarantees—committing your Kollmorgen MAG05-25041-007 to sustained excellence amid evolving nano-fab paradigms.`