Description:

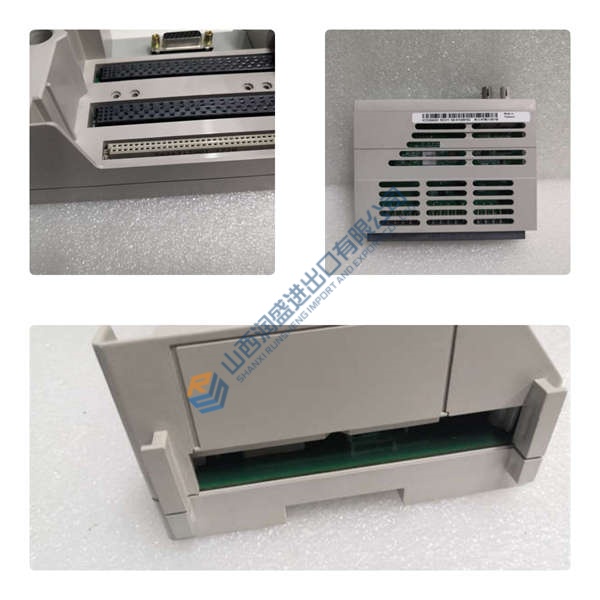

The Honeywell DCP711 50C012010H0 is a robust and highly reliable digital control panel designed for a variety of industrial automation applications. It offers precise control and monitoring for processes requiring stable and scalable digital I/O performance. As part of Honeywell’s advanced automation systems, the DCP711 50C012010H0 ensures seamless integration with existing industrial networks, enhancing overall control and data accuracy.

Application Scenarios:

In a large-scale chemical processing plant, the DCP711 50C012010H0 is used to manage sensors and actuators across critical control systems, including pressure, temperature, and flow regulation. By implementing this control panel, the facility achieved greater system stability, with reduced response times and fewer maintenance calls, leading to a 25% increase in overall production efficiency.

In a power generation facility, where real-time data acquisition is essential, the DCP711 50C012010H0 plays a key role in regulating turbine operations and controlling auxiliary systems. It processes digital signals reliably, ensuring that the system maintains optimal performance, even in harsh environmental conditions. This provides operators with real-time feedback, improving decision-making and reducing unplanned downtime.

Technical Principles and Innovative Values

- Innovation Point 1: Modular design enables users to easily expand or reconfigure the system as automation needs evolve, making the DCP711 50C012010H0 highly adaptable to various applications.

- Innovation Point 2: The DCP711 50C012010H0 supports both Modbus RTU and Profibus DP, offering flexibility to integrate with existing control systems and networks in diverse industrial environments.

- Innovation Point 3: With IP20 protection and a wide operating temperature range of -20°C to +60°C, the panel is capable of operating in tough, demanding industrial conditions, from factory floors to outdoor installations.

- Innovation Point 4: The DCP711 50C012010H0 offers enhanced digital signal processing, ensuring accurate data transmission and improving system response times, leading to greater operational efficiency.

- Innovation Point 5: Its compact size and flexible mounting options (DIN-rail or panel) make the module easy to install in constrained spaces, optimizing control cabinet layouts.

Compared to other control panels, the DCP711 50C012010H0 delivers superior adaptability, faster signal processing, and seamless integration with existing systems, reducing setup time and improving long-term reliability.

Application Cases and Industry Value

Case A – Chemical Processing

A large chemical processing plant implemented the Honeywell DCP711 50C012010H0 to manage key control points, including temperature and pressure regulation, across several production lines. This system upgrade allowed for smoother operation transitions, more reliable control, and better fault detection capabilities. As a result, the plant saw a significant reduction in downtime and increased production capacity by 20%, all while improving safety standards.

Case B – Power Generation Facility

In a power plant, the DCP711 50C012010H0 was integrated into the turbine control system to process real-time feedback from multiple sensors, including vibration, temperature, and pressure. The module’s ability to operate in a wide temperature range and handle harsh environmental conditions contributed to enhanced system stability, minimizing turbine wear and optimizing power output. Operator feedback highlighted improved diagnostic accuracy and reduced intervention time.

Related Product Combination Solutions

- DCP712: A higher capacity version of the DCP711 series, ideal for larger-scale systems requiring more I/O channels.

- DCP710: A similar digital control panel with fewer I/O channels, providing a cost-effective solution for smaller automation systems.

- Honeywell PLC Modules: These modules work seamlessly with the DCP711 50C012010H0 to create a full control solution, allowing users to expand their automation systems.

- Honeywell HMI Solutions: Integrated with the DCP711 50C012010H0, these human-machine interface systems provide visual control and feedback, enhancing the overall user experience.

- Honeywell SCADA Systems: Ideal for high-level supervisory control, DCP711 50C012010H0 integrates with SCADA systems to provide centralized control and monitoring of distributed assets.

These related products provide a complete ecosystem for users to enhance the capabilities of their automation systems, improving both efficiency and reliability.

Installation, Maintenance, and Full-Cycle Support

The installation of the DCP711 50C012010H0 is straightforward, with both DIN-rail and panel mounting options for easy integration into existing control cabinets. Clear wiring instructions and a simple configuration process make it quick to set up and deploy.

In terms of maintenance, the DCP711 50C012010H0 is designed for longevity, with low-maintenance components and easy-to-replace parts. Routine diagnostics can be performed through the system’s network interface, ensuring any potential issues are detected early. Honeywell’s global support network provides technical assistance, spare parts, and troubleshooting guidance to ensure optimal performance throughout the product’s lifecycle.

ASEA BROWN BOVERI 47810626-BK USPP 47810626BK

ASEA BROWN BOVERI 3HAB2812-1 NSPP 3HAB28121

ASEA BROWN BOVERI 3HAB2211-1-1 USPP 3HAB221111

ASEA BROWN BOVERI DSQC256A USPP DSQC256A

ASEA BROWN BOVERI EHW-250C-2P-1L USPP EHW250C2P1L

ASEA BROWN BOVERI EHW-250-WC-1L USPP EHW250WC1L

ASEA BROWN BOVERI C486G3753FI NSPP C486G3753FI

ASEA BROWN BOVERI 573300001 USPP 573300001

ASEA BROWN BOVERI ACS3114P11 NSFP ACS3114P11

ASEA BROWN BOVERI DSPC-150 USPP DSPC150

ASEA BROWN BOVERI GAB-1101V4 USPP GAB1101V4

ASEA BROWN BOVERI GAB-6101V7 USPP GAB6101V7

ASEA BROWN BOVERI GAB-6201V4 USPP GAB6201V4