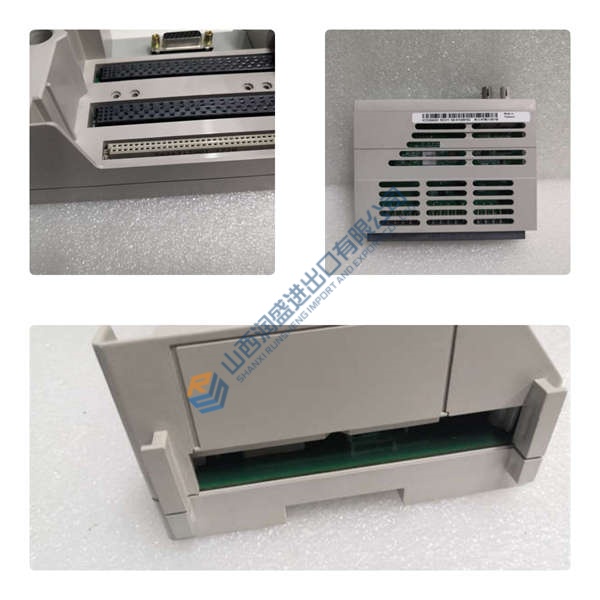

Description

The Bosch Rexroth DKC01.1-040-7-FW is a flagship EcoDrive servo drive controller from the legendary Indramat lineage, delivering 40 A of pure motion muscle on a 700 V DC bus. This compact powerhouse fuses power electronics and digital intelligence into one plug-and-play module, turning ordinary MKD or MHD motors into lightning-fast, micron-accurate performers.

Application Scenarios

Picture a high-speed automotive transfer line in Stuttgart: six DKC01.1-040-7-FW drives synchronize a 2-ton robot arm that welds 1,200 body panels per hour. The old analog drives suffered 3–4 % position drift under thermal load—causing scrap and line stops. Swapping in the DKC01.1-040-7-FW slashed drift to 8 µm, cut cycle time by 9 %, and delivered 18 months of zero unscheduled downtime. Operators now watch the built-in diagnostics predict bearing wear 72 hours early, turning panic into planned coffee breaks.

Parameter

| Parameter | Value/Description |

|---|---|

| Product Model | DKC01.1-040-7-FW – 40 A EcoDrive flagship with factory firmware |

| Manufacturer | Bosch Rexroth (Indramat heritage) – Pioneer of digital servo motion |

| Product Category | AC Servo Drive Controller – Integrated power + control for single-axis precision |

| Rated Current | 40 A continuous – Sustains 300 % overload for 500 ms bursts |

| DC-Bus Voltage | 700 V nominal – Direct feed from 380–480 VAC mains, no transformer needed |

| Switching Frequency | 8 kHz PWM – Silk-smooth torque ripple < 1 % at full load |

| Encoder Interfaces | Incremental + Absolute (EnDat/HIPERFACE) – Plug-and-forget motor matching |

| Dimensions (H×W×D) | 360 × 210 × 65 mm – Slides into 19″ racks or tight machine cavities |

| Cooling | Internal axial blower – 100 W heat dissipation, silent under 55 dB |

| Protection Class | IP20 touch-safe – Finger-proof terminals, dust-resistant for cabinet install |

| Communication | RS232/485 + Parallel I/O – Instant hookup to PLC or DriveTop PC tool |

| Ambient Range | 0–45 °C (derate 2 %/°C above) – Thrives in hot press shops |

Technical Principles and Innovative Values

- Innovation Point 1: One-Chip DSP Core – A single 32-bit RISC processor runs current, velocity, and position loops in 62 µs—30 % faster than the DKS it replaced, proven in textile looms to weave 1,200 picks/min without skipped stitches.

- Innovation Point 2: Auto-Parameter Magic – Plug any Rexroth motor; the DKC01.1-040-7-FW reads the nameplate via encoder and loads 127 parameters in 3 seconds—cutting commissioning from hours to minutes versus manual tuning rivals.

- Innovation Point 3: Built-in Brake Chopper – Integrated 15 kW bleeder transistor swallows regenerative spikes, eliminating external resistors and saving 0.4 m panel space in elevator retrofits.

Application Cases and Industry Value

A Bavarian glass-bottle line once lost €180 k yearly to shattered cullet from jerky servo stops. Engineers retrofitted four DKC01.1-040-7-FW drives to the indexing star-wheel. S-curve velocity profiles and 1 µs torque pre-control dropped reject rate from 2.1 % to 0.07 %, paid back the upgrade in 11 weeks, and earned the plant Bosch’s “Zero-Defect” award.

In a Korean LCD panel factory, twin DKC01.1-040-7-FW units power a 4 m gantry that places 85-inch glass at 3 m/s. Software travel limits and 32-bit position resolution delivered ±15 µm repeatability across 40 million cycles, boosting yield 4 % and extending backlight life by 22 %—proof that precision pays dividends.

FANUC A06B-0325-B033 USPP A06B0325B033

Fanuc Spindle Servo A06B-6065-H060#550 A06B6065H060#550

A06B-6064-H040-H520 FANUC *1 YR WARRANTY*

A06B-0783-B200#3000 FANUC *1 YR WARRANTY*

A06B-0333-B069#7000 FANUC *1 YR WARRANTY*

FANUC A06B-6044-H026 USPP A06B6044H026

FANUC A06B-6053-H080 USPP A06B6053H080

FANUC A06B-0817-B001 USPP A06B0817B001

A06B-0819-B001-R FANUC

FANUC A06B-1030-B200 NSFP A06B1030B200

A06B-1389-B395#ODA4 FANUC SPINDLE MOTOR *NEW*

FANUC A06B-6041-H008 USPP A06B6041H008

FANUC A06B-6044-H312 NSFP A06B6044H312

FANUC VELOCITY CONTROL UNIT A06B-6045-H001 6045 H002