Key Technical Specifications

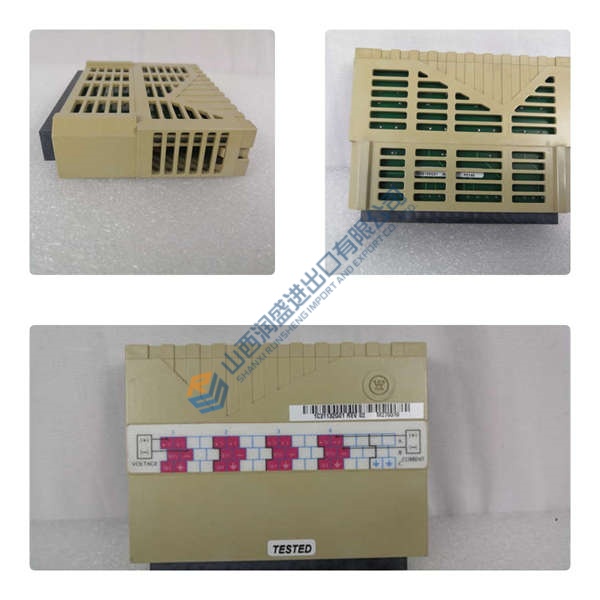

- Product Model: HIEE300900R0001 PPC322BE

- Manufacturer: ABB

- System Platform: ABB Advant OCS

- Module Type: Process controller / CPU module

- Processor Architecture: 32-bit industrial microprocessor (ABB proprietary)

- Control Execution Model: Deterministic cyclic scan with priority task handling

- Program Memory: Battery-backed RAM with non-volatile storage support

- I/O Capacity: Supports large-scale local and remote I/O via Advant OCS subsystems

- Communication Interfaces: Advant OCS backplane bus, system communication channels

- Redundancy Capability: Supports system-level redundancy (controller and power, configuration dependent)

- Power Supply Requirement: Supplied via Advant OCS rack backplane

- Power Consumption: <30 W

- Self-Diagnostics: CPU watchdog, memory integrity check, internal temperature monitoring

- Operating Temperature: 0 to +55 °C

- Storage Temperature: −25 to +70 °C

- Mounting Type: Plug-in module for Advant OCS control rack

- Certifications & Compliance: CE compliant, IEC 61131-2 industrial control standards

Technical Architecture & Functional Positioning

Architecture Analysis

The PPC322BE process controller is positioned at the core control layer of the ABB Advant OCS architecture. It is responsible for executing process control algorithms, sequencing logic, interlocks, and coordination of distributed I/O and communication tasks. All field data and operator commands ultimately converge at this controller, making it a central element for plant-wide control integrity.

From a system architecture standpoint, the controller is designed around a deterministic scan-based execution model optimized for continuous industrial processes. Control tasks are executed cyclically with predictable timing, ensuring stable closed-loop behavior even under high I/O loading. The high-reliability backplane interface enables fast and deterministic data exchange with I/O modules, communication processors, and redundant controller partners where configured.

The engineering value of this design lies in predictability, robustness, and long-term stability. In industries such as power generation, oil and gas, pulp and paper, and metals processing, control systems are expected to operate continuously for years. Integrated watchdog supervision, memory checking, and self-diagnostics allow early detection of abnormal conditions, reducing the risk of uncontrolled failures. When deployed in redundant configurations, the controller supports seamless switchover, maintaining process continuity during hardware faults or maintenance interventions.

Typical Application Scenarios

- Applied in power generation plants for boiler, turbine, and balance-of-plant control

- Used in chemical and petrochemical facilities for continuous process regulation

- Serves as an OEM-compatible replacement for legacy Advant OCS controller installations

- Supports system life-extension projects where Advant OCS remains in operation

- Utilized in industrial automation simulation and training platforms

BRAD HARRISON 702P401 MULTIPORT INTERCONNECT SYSTEM NEW

BRAD HARRISON 803P802 8-PORT JUNCTION BOX MICROFAST NEW

BRAD HARRISON 302002A01F120 CABLE

BRAD HARRISON 301002A01F20 CABLE

2 Brad Harrison 103000A01F030 3′ 3P Female Cord New

BRAD HARRISON DN11A-M210 DEVICENET CORD 5P 21M NEW

Brad Harrison 301000A0F120

1 NEW BRAD HARRISON 47025 20′ MINI-CHANGE EXTENSION NIB

1 NEW BRAD HARRISON 208000A04M050 PVC CABLE NIB

Brad Harrison 35601 Control Connector 12p Fe Receptor

BRAD HARRISON WOODHEAD 302001K04M050 MINI CORDSET * NEW

42895T BRAD HARRISON NEW

BRAD HARRISON 22902 NSFP 22902

BRAD HARRISON 706000D02M100 NSFP 706000D02M100

BRAD HARRISON 61041-M030 NSFP 61041M030

Brad Harrison/Woodhead 332021A01F120/47446-90 NEW

New Brad Harrison 7P Mini-change Cordset 207000A01F6501