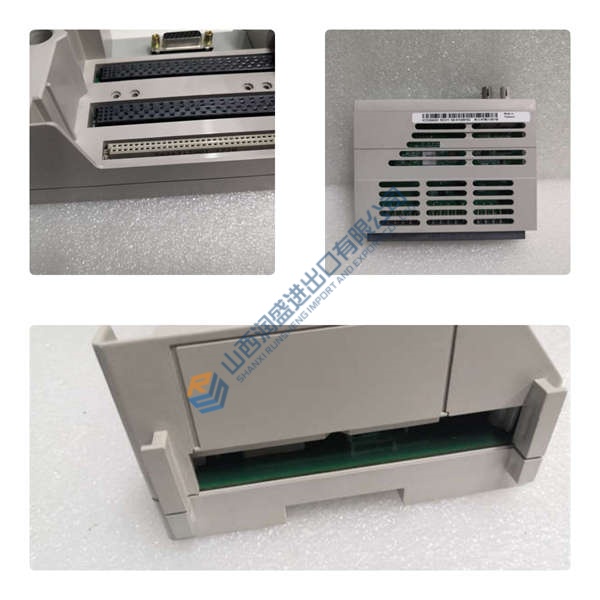

- Model: IS220PSVOH1B

- Manufacturer: GE

- Core Function: Serves as a servo interface I/O pack that provides precise control and feedback for electro-hydraulic servo valves in turbine applications, interfacing between the controller and terminal board for valve positioning.

- System Compatibility: Compatible with GE Mark VIe and Mark VIeS distributed control systems, including Speedtronic turbine platforms.

- Supply Status: Available as new surplus, refurbished, or repair/exchange; current production status varies by supplier network.

- Warranty Standard: 12-month functional warranty, fully tested.

Key Technical Specifications

- Product Model: IS220PSVOH1B

- Manufacturer: GE

- System Platform: Mark VIe

- Power Supply Voltage: 28 V DC nominal (from terminal board), with operational range typically 24-32 V DC for reliable servo driver operation.

- Power Consumption: Approximately 10-15 W, minimizing thermal load in dense control cabinets.

- Communication Interfaces: Dual 100 Mbps Ethernet ports for IONet connectivity, supporting redundant high-speed communication to Mark VIe controllers.

- Servo Outputs: 2 independent servo valve current outputs (typically 4-20 mA or ±10 V configurable), enabling precise positioning of steam/gas turbine valves.

- LVDT Inputs: 8 channels for Linear Variable Differential Transformer feedback, providing high-resolution position sensing with 16-bit accuracy.

- Pulse Rate Inputs: 2 channels, supporting speed or flow feedback signals critical for governor control loops.

- Operating Temperature Range: -30°C to +65°C, suited for industrial environments including turbine halls with elevated ambient conditions.

- Humidity Tolerance: 5% to 95% non-condensing, ensuring reliable performance in humid or condensing environments.

- Dimensions: Compact pack design approximately 10 cm x 20 cm x 5 cm (typical for Mark VIe I/O packs), optimized for DIN-rail or panel mounting via terminal board.

- Weight: Approximately 0.8 kg, allowing straightforward installation and replacement.

- Mean Time Between Failures (MTBF): >100,000 hours (typical for Mark VIe series I/O), contributing to high system availability in continuous operation.

- Certification Standards: CE marked, compliant with UL 508 for industrial control equipment and RoHS directives.

- Response Time: Servo loop update rates <5 ms, essential for fast valve response in dynamic load changes.

Technical Architecture & Functional Positioning

The IS220PSVOH1B functions as a field-level I/O pack in the Mark VIe architecture, positioned directly at the interface between the control network and the servo terminal board (typically TSVO). It digitizes feedback signals from LVDTs and pulse inputs while driving servo valve coils with precise current or voltage commands. This placement in the distributed I/O layer enables localized processing, reducing wiring distances and latency compared to centralized systems. The pack includes onboard processing, local power regulation, and temperature monitoring, allowing independent operation and diagnostics without constant reliance on the main controller.

Core technologies include dual Ethernet interfaces for redundant IONet communication, ensuring fault-tolerant data paths in TMR (Triple Modular Redundancy) configurations common in critical turbine applications. The servo driver circuitry employs high-precision DACs and current amplifiers with feedback loops to maintain valve position accuracy under varying hydraulic pressures. Built-in diagnostics monitor coil continuity, LVDT excitation, and output current, detecting anomalies such as shorts or open circuits in real time. These features solve key engineering challenges: maintaining sub-millimeter valve positioning for precise speed/load control, mitigating electromagnetic interference in high-power turbine environments, and enabling predictive maintenance through detailed fault reporting.

In turbine control hierarchies, the module’s design supports bumpless transfer in redundant setups and rapid response to setpoint changes, directly impacting overall plant efficiency and protection against overspeed or instability conditions.

BOSCH DECKEL VM 60/R-T DC 520V 60A SERVO DRIVE

LABOR THYRISTOR REGLER DRIVE GN 6 DZ 160/175-24-4 Q 80

Cutler Hammer Non Rev Starter A200M4CAC Sz Size 4 NIB

Siemens DC Inverter Simovert VC 6SE7021-3TB61 6SE70213T

US Electric Vari Drive 20HP 3PH VEUGH 220/440V Cy 60

BLOWER 7X9 7 X 9 184821 K1282-02 K128202

Goulds Centrifugal Pump 3196 MTX 3″x1-1/2″ B-1650MDSNP

HOOVER 304 S/S TANK 550 GALLON chemical tote TANK

GUILLOTINE 13 3/4″ H X 24″ W OPENING RUBBER CUTTER CUT

UV TECHNIQUE ELECTRONIC FLUORESCENT LAMP BALLAST ALP51

TELEMECANIQUE ALTIVAR 66 DRIVE 5-7.5 HP ATV66U72N4 NEW

BALTIMORE AIRCOIL COOLING TOWER FXT-16C

RETA-LABOD THYRISTOR REGLER DRIVE GN 6 DZ 160/175-24-4Q

NEW VAISALA WET BULB TRANSMITTER HMP235 D1B1A1AA52A2A3P

CUTLER HAMMER NON REV STARTER Size sz 3 W200M3CFC NEW

Square D I-Line Busway PQ-4640 PQ4640 400A 400 amp a

Reliance Electric PC Control Regulator 0-51851 051851

Duff-Norton 2 Ton Coffing Cable Hoist 18′ Lift WR 4014