Description

Product Overview

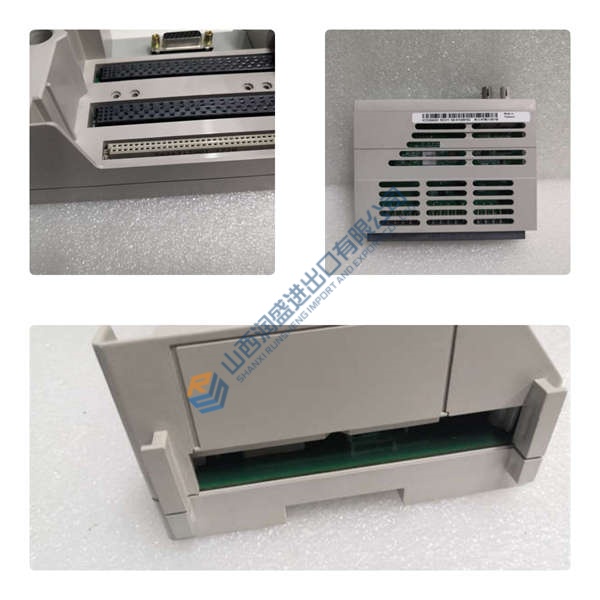

The Honeywell 51304518-100 Advanced Control Module is a foundational component within Honeywell’s renowned TDC-3000 Distributed Control System (DCS), serving as the brain for sophisticated process management and control applications. As a critical part of the Universal Control Network (UCN), this module is engineered to execute complex control strategies with exceptional reliability and precision, effectively bridging the gap between field devices and the system’s human-machine interface (HMI). Its robust design ensures continuous operation in demanding industrial environments, providing a high degree of availability that is essential for mission-critical processes. The Honeywell 51304518-100 module is not merely a controller; it is a vital enabler of process optimization, allowing for dynamic adjustments, comprehensive data collection, and seamless integration within a vast industrial ecosystem.

This module is central to the TDC-3000 platform’s value proposition, which centers on delivering a scalable, fault-tolerant, and high-performance automation solution. The Honeywell 51304518-100 empowers facilities to achieve tighter process control, reduce operational variability, and enhance overall plant safety and efficiency. Its architecture supports a wide range of control algorithms and can manage a significant number of I/O points, making it a versatile choice for a diverse set of industrial applications. The inherent redundancy capabilities of the TDC-3000 system, leveraged by modules like the Honeywell 51304518-100, ensure that a single point of failure does not compromise the entire control loop, thereby safeguarding production continuity and protecting valuable assets.

Technical Specifications

Main Features and Advantages

The Honeywell 51304518-100 Advanced Control Module stands out due to its powerful combination of processing capability, robust reliability, and seamless system integration, which collectively provide a significant competitive advantage in industrial automation. Its core function as the central processing unit for process control within the TDC-3000 DCS allows it to execute complex control strategies in real-time. This capability is crucial for industries where precise control of variables such as temperature, pressure, and flow is paramount. The module’s design incorporates advanced diagnostics and self-checking features, enabling predictive maintenance and ensuring high system availability by proactively identifying and alerting operators to potential issues before they lead to downtime. This focus on reliability and uptime is a key value proposition of the Honeywell 51304518-100.

Another major benefit is its deep integration into the Universal Control Network (UCN) architecture. This networked approach facilitates high-speed, secure communication between the control module and other system components, including I/O modules and operator stations. This ensures that process data is distributed efficiently and that control actions are executed with minimal latency. The Honeywell 51304518-100 is also known for its backward compatibility, which allows it to be integrated into existing TDC-3000 installations, providing a path for system expansion or modernization without requiring a complete rip-and-replace of the entire control infrastructure. This protects a company’s initial investment and minimizes the costs and risks associated with system upgrades. The flexibility and scalability of the Honeywell 51304518-100 make it a preferred choice for organizations seeking a long-term, stable, and high-performance automation solution.

Application Field

The Honeywell 51304518-100 Advanced Control Module is a cornerstone of process control, widely deployed across a spectrum of industries that demand high-level automation, reliability, and precision. Its primary application is in the continuous process industries where the stable and accurate control of complex variables is essential. For instance, in the oil and gas sector, the Honeywell 51304518-100 is used in refining, petrochemical, and pipeline operations to manage distillation columns, reactors, and compressor stations, ensuring product quality and safety while maximizing throughput. In the chemical industry, it provides the granular control needed for batch processing and continuous reactions, maintaining strict operating parameters to prevent off-spec products and hazardous conditions.

Beyond these core applications, the Honeywell 51304518-100 is also prevalent in power generation facilities, where it is used to manage boiler controls, turbine-generator systems, and plant-wide balance-of-plant operations. Its ability to handle large-scale, high-speed data acquisition and control is crucial for maintaining grid stability and efficiency. The module’s robust design also makes it suitable for the pulp and paper industry, controlling processes from pulping and bleaching to paper machine operations, as well as in water and wastewater treatment, where it ensures regulatory compliance by managing purification and distribution processes. The versatility and proven performance of the Honeywell 51304518-100 make it a go-to solution for any large-scale industrial operation requiring a reliable and high-performance DCS.

Related Products

The Honeywell 51304518-100 Advanced Control Module is part of a larger ecosystem of TDC-3000 components. Here are some related models and their relationships:

- Honeywell 51304517-100: This is the Process Manager (PM) module, which is an earlier version or closely related variant. It performs similar control functions but may have different hardware or firmware revisions.

- Honeywell 51304547-100: This is a UCN I/O Link Interface module. It serves as the gateway for I/O modules, enabling the 51304518-100 to communicate with field devices.

- Honeywell 51304506-100: This is a UCN gateway module, which facilitates communication between the UCN and other network types, extending the reach of the control system.

- Honeywell 51304604-100: A UCN to LCN Gateway, providing connectivity to the Local Control Network (LCN) for communication with older TDC-3000 components and operator stations.

- Honeywell TC-IXL071: This is an Industrial Ethernet Module for Experion PKS, which represents a more modern communication platform, showing the evolution from the UCN-based 51304518-100 to newer systems.

Installation and Maintenance

Pre-installation preparation: Before installing the Honeywell 51304518-100 Advanced Control Module, ensure the destination chassis slot is clean, free of dust, and that the power supply for the rack is properly disconnected to prevent electrical shock. Verify the module’s hardware and firmware revisions are compatible with the existing system configuration and that the physical mounting location is secure and provides adequate ventilation. It is essential to handle the Honeywell 51304518-100 with anti-static precautions, using a grounded wrist strap to protect its sensitive electronic components from electrostatic discharge. Confirm that all associated cables and connectors are in good condition and properly identified to facilitate a smooth and accurate installation process.

Maintenance recommendations: Regular maintenance for the Honeywell 51304518-100 primarily involves visual inspections and environmental management. Periodically check the module and its surrounding rack for any signs of physical damage, corrosion, or overheating. Ensure that cooling fans (if present in the rack) are functioning correctly and that air filters are clean to maintain optimal operating temperature. It is also recommended to review system diagnostics logs for the Honeywell 51304518-100 to detect any performance degradation or soft errors that may indicate a developing issue. When performing any maintenance or replacement, always follow the system’s defined shutdown and restart procedures to prevent disruption to process control. This proactive approach ensures the long-term reliability of the Honeywell 51304518-100 and the entire control system.

KEYENCE LASER AMPLIFER FS-V31 & LASER SENSOR FU-66Z NEW

NEW MITSUBISHI MELSEC Q QY50 ( NIB FS )

Yokogawa Temperature Control SMST Yew Series 80 New!

NIKON EL-NIKKOR 135MM 1:5.6 LENS

OMRON CAMERA CABLE F309 – VSR2 NEW!

KEYENCE LV – H37 Laser Sensor Head New!

MITSUBISHI MELSEC Q SERIES Q55B EXTENSION BASE UNIT NEW

DEL-TRON Positioning Stage LRS3-1 & MCG Servo Motor LNC

MITSUBISHI MELSEC A1S61PN POWER SUPPLY ( NIB )

OMRON DIJITAL TIMER H5CX-AD H5CXAD NEW ( NIB !!! )

MITSUBISHI MELSEC A1SX41 Input Unit NIB !

Omron H5F-KB Time Switch 24H Weekly New NIB