Description

Description:

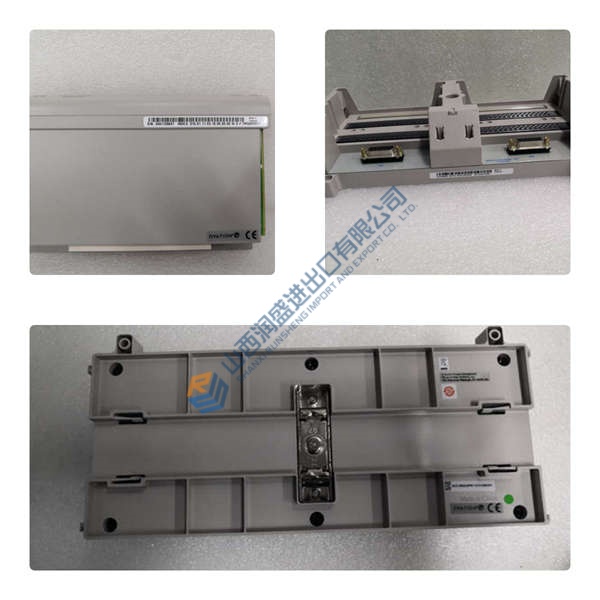

The ABB AO2000 URAS26 B05907-24541 is a specialized infrared photometer analyzer module, designed as a core component of the modular ABB Advance Optima series. This module uses the NDIR (Non-Dispersive Infrared) principle to accurately and reliably measure the concentration of various gases like CO, CO₂, SO₂, NO, and CH₄. Its robust, compact design and selective measurement capabilities make it an ideal solution for a wide range of industrial process control and environmental monitoring applications.

Application Scenarios:

In the cement manufacturing industry, the efficiency and environmental impact of the kiln process are directly tied to the precise control of gas concentrations. Monitoring carbon monoxide (CO) in the kiln’s exhaust is a critical safety and process control measure. Too much CO indicates incomplete combustion and potential energy waste, while also posing a safety risk. This is where the AO2000 URAS26 proves invaluable. By continuously analyzing the CO concentration in the flue gas, it provides real-time data that allows operators to fine-tune the combustion process. This ensures maximum fuel efficiency, reduces raw material waste, and helps the plant comply with strict emissions regulations. The reliable and accurate data from the AO2000 URAS26 is the foundation for an optimized, safe, and cost-effective operation.

Parameter:

Technical Principles and Innovative Values:

- NDIR Photometry with a Double-Layer Detector: The AO2000 URAS26‘s core innovation is its double-layer infrared detector. This design significantly improves selectivity by minimizing cross-interference from other gases in the sample. As infrared radiation passes through the gas, the target gas absorbs specific wavelengths. The double-layer detector’s internal reference cell and measurement cell work together to precisely measure this absorption, providing an exceptionally accurate and stable reading.

- Compact and Robust Design: The AO2000 URAS26 is built for the rigors of industrial environments. Its compact, modular form factor makes it easy to integrate into a central system, reducing the overall footprint and simplifying installation. The robust design ensures long-term reliability and low maintenance, even in applications with challenging gas matrices.

- Fast and Low-Maintenance Operation: With a typical T₉₀ response time of less than 5 seconds, the AO2000 URAS26 delivers rapid process feedback, which is crucial for real-time control applications. While it requires periodic calibration, its stable measurement and robust design mean maintenance is not a frequent burden, leading to a lower total cost of ownership.

Application Cases and Industry Value:

A large power generation plant was struggling with inefficient boiler combustion, leading to high fuel costs and elevated CO emissions. After installing an ABB AO2000 URAS26 as part of a multi-analyzer system, they were able to get precise, real-time CO readings from their flue gas. The data from the AO2000 URAS26 enabled them to implement a more responsive control strategy for the boiler, allowing them to optimize the air-to-fuel ratio. This resulted in a measured 2% increase in boiler efficiency, a substantial saving in fuel costs, and a significant reduction in their carbon footprint, demonstrating the direct business value of accurate gas analysis.

Installation, Maintenance, and Full-Cycle Support:

The AO2000 URAS26 module is designed for easy installation, simply sliding into a slot in the main central unit. Its robust design minimizes the need for frequent maintenance. While periodic calibration is required using zero gas and span gas, the stable NDIR technology ensures long intervals between these procedures. The modular nature of the system simplifies troubleshooting and part replacement, reducing potential downtime.

We offer comprehensive support for the entire lifecycle of your AO2000 URAS26. Our technical teams provide remote and on-site assistance for commissioning and troubleshooting. We also offer training for your staff to ensure confident operation and maintenance. By providing genuine spare parts and expert service, we guarantee that your analyzer will deliver accurate and reliable performance for years to come, protecting your investment and ensuring operational excellence.

Contact us for a customized solution.

Chatillon TCD500 Tension Meter

Lot Lexmark 12A5950 Glossy Laser Paper

Tektronix TDS714L Oscilloscope Color 500MHz 4Ch 500MSa

74-70020110 ROTATING ELEMENT Turbine

Aircel Systems R20 Refrigerated Compressed Air Dryer 2

NITTAN TECHNO ACM-20 CIMPING MACHINE W/ DIE

LEAR SIEGLER MC2000 EMISSIION MONITOR TRANSCEIVER

PRYSMIAN 288F OFNR SMF-28E RILT OPTICAL CABLE 700FT

FALK BLENDER MINE SMELTER ROCK

REX WH82 Welded Steel Mill Chain

TECHNOS 73-00200020 RADIAL FAN WHEEL

ENTEC NATIONAL ENGINEERED CALIPER BRAKING SYSTEM