Description

Detailed parameter table

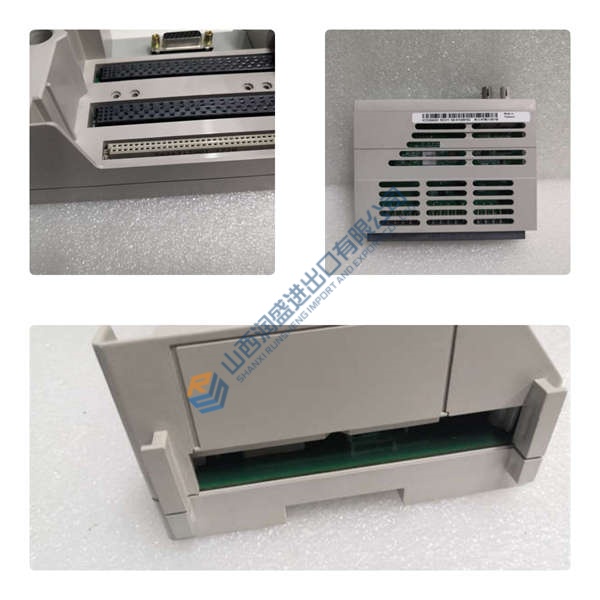

Product introduction

The ABB Advance Optima AO2040 is a sophisticated, modular industrial process gas analyzer system designed for continuous and reliable measurement of gas components in industrial processes. As a key product within the ABB Advance Optima family, the ABB Advance Optima AO2040 stands out for its high degree of flexibility and scalability. It is an integrated system housed in a 19-inch chassis, which includes a central unit, a display/keyboard, a power supply, and space for up to four integrated analyzer modules. This design allows the ABB Advance Optima AO2040 to serve as a compact yet powerful solution for a wide range of analytical tasks.

This system’s core value lies in its ability to offer a single, standardized platform for various measurement technologies. Users can choose from different high-performance analyzer modules—such as NDIR photometers, thermal conductivity analyzers, oxygen analyzers, and UV-Vis photometers—to suit their specific application needs. This modularity not only simplifies system integration and operation but also ensures the long-term security of the investment, as the ABB Advance Optima AO2040 can be easily upgraded or expanded with additional functionalities as requirements evolve. The ABB Advance Optima AO2040 is positioned as a cornerstone of process optimization and quality control, playing a critical role in enhancing efficiency, safety, and environmental compliance across diverse industries.

Core advantages and technical highlights

The ABB Advance Optima AO2040 sets a new standard for process gas analysis with its intelligent design and powerful technical features. A primary functional innovation is its ability to simultaneously house up to four different analyzer modules. This multi-component capability reduces the need for multiple single-analyzer systems, thereby simplifying installation, maintenance, and wiring. This consolidation not only saves physical space but also improves data synchronization and overall system reliability. The ABB Advance Optima AO2040‘s dedicated architecture ensures seamless communication and power distribution to all integrated modules.

Reliability is a cornerstone of the ABB Advance Optima AO2040. It is built with industrial-grade materials and a durable, compact form factor, making it suitable for prolonged operation in demanding environments. This resilience ensures a long service life and minimizes the risk of system downtime due to component failure. From a compatibility standpoint, the ABB Advance Optima AO2040 is meticulously engineered to work in harmony with various ABB analyzer modules, ensuring a “plug-and-play” experience and reducing configuration time and complexity during system setup.

The system’s advanced calibration features are a significant highlight. The ABB Advance Optima AO2040 supports automatic calibration using ambient air or an integrated calibration cell, which dramatically reduces the need for frequent use of costly and cumbersome test gas cylinders. This feature not only lowers operational costs but also minimizes manual intervention, freeing up technical staff for other tasks. A self-check function proactively signals when maintenance is required, preventing unexpected downtime and ensuring continuous, reliable operation.

Typical application scenarios

The ABB Advance Optima AO2040 is ideally suited for a wide range of industrial applications that require precise and reliable multi-component gas analysis. In the power generation and waste incineration industries, it is critical for Continuous Emissions Monitoring Systems (CEMS), where it can simultaneously measure pollutants like SO₂, NOx, CO, and O₂ to ensure compliance with strict environmental regulations. The multi-module capability of the ABB Advance Optima AO2040 makes it a highly efficient and cost-effective solution for these complex monitoring requirements.

In the chemical and pharmaceutical industries, the ABB Advance Optima AO2040 is deployed in process control systems to manage and monitor a variety of variables in a recipe-based or continuous process. Its ability to handle multiple analog and digital signals with high precision makes it invaluable for maintaining consistent product quality and ensuring compliance. In a typical automation project, the ABB Advance Optima AO2040 would be mounted in a control room or analyzer shelter, where it serves as the central hub for multiple gas analysis points. This setup not only centralizes the analytical data but also provides a durable and stable platform that is easy to troubleshoot and maintain, significantly enhancing the overall reliability and performance of the automation system.

Related model recommendations

The ABB Advance Optima AO2040 is part of a larger ecosystem of ABB analytical products. Other related models include:

Advance Optima AO2020: The smaller version of this system, which can house only one analyzer module. It is a good choice for single-component analysis or space-constrained applications.

Uras 26: An NDIR photometer analyzer module that can be integrated into the ABB Advance Optima AO2040 system for highly selective and sensitive measurement of specific gas components like CO₂ and CO.

Magnos 206: A paramagnetic oxygen analyzer module compatible with the ABB Advance Optima AO2040, used for measuring oxygen concentration for safety and combustion control.

Caldos 27: A thermal conductivity analyzer module also designed for integration into the ABB Advance Optima AO2040, typically used for measuring binary gas mixtures like H₂ in N₂.

LIMAS 21: A UV-Vis photometer module that can be integrated into the ABB Advance Optima AO2040 for measuring gases like NO, NO₂, and SO₂.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the ABB Advance Optima AO2040, ensure that the installation environment is stable and meets the specified temperature and humidity ranges. Confirm that the power supply is correct for the unit and that all necessary communication cables and gas lines are available. The 19″ chassis of the ABB Advance Optima AO2040 is designed for rack mounting, so ensure the rack is securely fixed. Proper ventilation is crucial to prevent overheating. It is also essential to correctly connect the sample gas lines, purge gas lines, and drain lines as per the detailed instruction manual for the specific configuration of the ABB Advance Optima AO2040.

Maintenance suggestions: The ABB Advance Optima AO2040 is designed for minimal maintenance. Regular checks should include inspecting the sample conditioning system for filter replacement or condensation buildup. The automatic calibration feature significantly reduces the need for manual calibration, but periodic checks with a certified gas standard are recommended to verify accuracy. In case of an alarm, the system’s self-diagnosis features will guide troubleshooting. For complex issues, consulting the detailed manual for the specific analyzer module and the central ABB Advance Optima AO2040 unit is advised. Keeping spare parts such as filters and fuses on hand will ensure quick resolution and minimal downtime.

NWL Transformer 260 kVA 460 500/24000 27000 260kVA oil

Square D QED BPO364 Bolt Loc Switch Panel 4000 Amp A 4W

Toshiba VFAS14132KPCA1 Inverter VF-AS1 VS Drive 200 HP

Square D QED 2x NEF Breaker Panel 4000 Amp A 4W Ground

Cutler Hammer CH Advantage W240M6CFC Size Sz 6 Starter

Fanuc A06B-6105-H002 6 Axis Servo Amplifier REM

GE Limitamp Multilin Starter 1250 HP 4160 V CR7160B118G

ITE GOULD BBC ABB K3000 K 3000 3000A Air Breaker LS

Square D QED Breaker Panel PXF361000LSI 1200 Amp A 4W

Cutler Hammer CH Advantage W240M6CFC Size Sz 6 Starter

Graco Magna Drum Pump Premier 800 Air 222-800 C59792

Cutler Hammer CRD CRD316T33W 1600A 1600Amp 1600 A

Digitrip 310 TRIP UNIT RES1600LS W/AUX AND SHUNT TRIPS

Cutler-Hammer Magnum DS MDS630 3000 Amp Digitrip 520 A

Yaskawa CACR-UP130AAB Robot Servo Unit CACRUP130AAB

Allen Bradley AB 1336S-B200-AN-EN-L6 200/250 HP V Drive

Toshiba Vacuum Contactor YDCT Motor Starter 600 HP 460V

Square D Schneider Masterpact NW12L 1200 Amp 1200A NIB

Westinghouse A200M6CXZ2DX Size 6 A200M6C Motor Starter