Description

Detailed parameter table

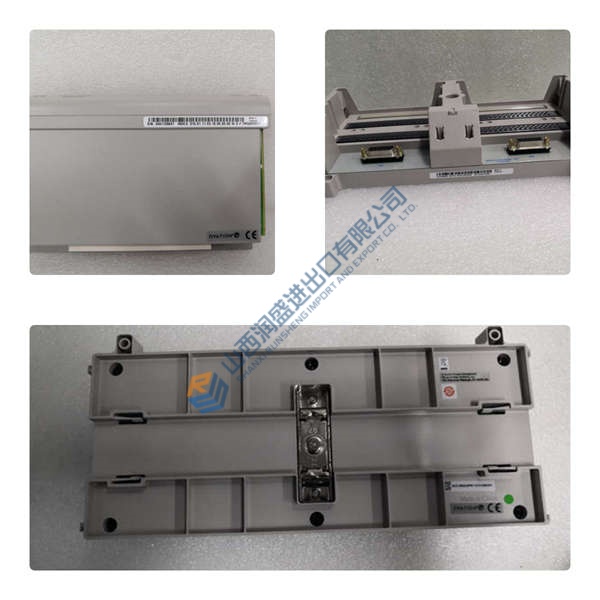

| Parameter name | Parameter value |

|---|---|

| Product model | CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW |

| Manufacturer | Bosch Rexroth |

| Product category | IndraDrive BASIC Universal Double-Axis Control Unit |

| Axes Supported | 2 (Dual-Axis) |

| Master Communication | Multi-Ethernet (SERCOS III, PROFINET IO, EtherCAT, EtherNet/IP) |

| Slave Communication | EtherCAT (EC) |

| Encoder Interface | Multi-Encoder (Hiperface, EnDat 2.1, EnDat 2.2, TTL) |

| Safety Technology | Safe Motion (FSOE), Safe Torque Off |

| Operating Temperature | 0…+45 °C (derating above 45 °C) |

| Dimensions (W x H x D) | 108 x 230 x 105 mm |

| Weight | 1.2 kg |

| Power Supply Voltage | 24 VDC (Logic), Compatible with ECODRIVE Power Stages |

| Pulse Frequency | Up to 20 kHz |

Product introduction

Within the sophisticated landscape of motion control systems, the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW emerges as a compact powerhouse in Bosch Rexroth’s IndraDrive ecosystem. This BASIC Universal double-axis control unit is meticulously engineered to orchestrate synchronized operations across two independent axes, integrating advanced digital control algorithms with seamless fieldbus integration. Positioned as an economical yet feature-rich component in the CDB series, the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW excels in environments where space constraints demand multifunctional hardware without sacrificing precision or expandability. Its primary role lies in bridging high-level automation controllers to servo amplifiers, enabling deterministic command execution for tasks ranging from position interpolation to velocity profiling, thereby elevating the overall efficacy of integrated manufacturing lines.

At the heart of the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW are its versatile communication architectures: Multi-Ethernet for master-level connectivity supporting protocols like SERCOS III and EtherCAT, complemented by EtherCAT slave interfaces for real-time data exchange with downstream devices. This configuration supports multi-encoder evaluation for closed-loop feedback, ensuring sub-millisecond response times critical for dynamic applications. As part of the IndraDrive platform, the unit facilitates modular scaling, where parameters for each axis can be stored on an optional MultiMediaCard, streamlining commissioning and diagnostics via the IndraWorks engineering suite. The Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW thus delivers tangible value by optimizing energy efficiency and reducing cabling overhead, fostering resilient automation architectures that adapt to fluctuating production rhythms.

Moreover, the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW incorporates inherent safety mechanisms, including Safe Motion technology compliant with EN ISO 13849-1, to safeguard personnel and machinery during high-speed operations. Its firmware-agnostic design—denoted by the FW suffix—allows for tailored software loading, ensuring longevity in evolving industrial paradigms. By harmonizing compactness with robust functionality, this control unit not only enhances throughput in synchronized multi-axis setups but also empowers engineers to realize cost-effective, future-ready control strategies within the broader IndraDrive framework.

Core advantages and technical highlights

Functional innovation drives the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW forward, embedding dual-axis independence within a single enclosure to execute coordinated trajectories without inter-axis latency. This capability shines in applications requiring harmonic motion, where the unit’s integrated function modules handle position, speed, and torque control modes interchangeably, supporting up to 16 technology functions like electronic gearing or camming. The Multi-Ethernet master interface decouples protocol dependencies, allowing seamless protocol switching via parameterization, while the dual EtherCAT slave ports enable daisy-chaining of up to 99 devices per segment, amplifying system granularity in distributed topologies.

Performance benchmarks underscore the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW‘s prowess, delivering cycle times as low as 31.25 µs for SERCOS III synchronization and jitter under 1 µs in EtherCAT mode, courtesy of its high-speed DSP core. With a 20 kHz current control loop and vector-oriented algorithms, it sustains peak torques up to 400% overload for dynamic acceleration profiles, all while maintaining thermal equilibrium through intelligent derating from 45 °C onward. The unit’s 24 VDC logic supply decouples from high-voltage power stages, ensuring stable operation across ECODRIVE variants, and its onboard parameter memory—expandable via MMC—facilitates offline cloning for rapid multi-unit deployments.

Reliability fortifies the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW against industrial rigors, boasting an MTBF exceeding 200,000 hours per Telcordia SR-332 calculations and IP20-rated enclosure resilient to 5-500 Hz vibrations at 1 g RMS. Safety integration via FSOE (Fail-Safe over EtherCAT) achieves SIL 3/PLe certification, with dual-channel monitoring for safe stop and speed limiting, mitigating risks in collaborative robotics. Overload protection circuits guard against short circuits up to 10 A, and EMC compliance to EN 61800-3 Class A ensures noise-free coexistence in mixed-signal cabinets.

Compatibility permeates the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW‘s architecture, interfacing natively with IndraDyn motors and HMx inverters through standardized X8/X9 connectors, while optional slots accommodate analog I/O expansions or encoder emulation cards for legacy retrofits. Its firmware ecosystem supports hot-swapping with CSB02 single-axis siblings, and integration with OPC UA via gateway modules bridges to IIoT platforms, future-proofing investments.

Ease of use streamlines workflows with the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW, featuring an intuitive LED status array for axis health and a USB service port for direct IndraWorks connectivity, enabling wizard-guided parameterization in under 30 minutes. DIN-rail mounting and tool-free terminal access expedite panel integration, complemented by self-diagnostic routines that log faults with timestamps for predictive analytics, rendering complex dual-axis tuning accessible to field technicians without specialized training.

Typical application scenarios

In precision metalworking shops, the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW orchestrates dual-spindle CNC lathes, where its EtherCAT slave synchronization aligns feed axes to micrometer tolerances amid coolant mists and chip debris. Under continuous 24/7 cycles with thermal loads nearing 40 °C, the unit’s derating logic sustains 16 kHz loops for vibration-free surfacing, addressing machinists’ imperatives for scrap minimization and tool life extension—yielding up to 15% productivity gains in high-mix/low-volume runs by preempting synchronization drifts through real-time drift compensation.

Packaging automation lines harness the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW for intermittent form-fill-seal processes, coupling it to servo-driven fillers and sealers via SERCOS III for phase-locked filling at 200 cycles per minute. In humid, adhesive-laden atmospheres, its IP20 sealing and FSOE safety halts prevent overtravel during web jams, fulfilling packagers’ compliance needs under EU Machinery Directive 2006/42/EC while optimizing throughput—evidenced by reduced changeover times from hours to minutes through MMC-stored recipes that adapt to diverse pouch formats without recabling.

Renewable energy assembly, particularly solar panel stringers, deploys the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-NN-FW to coordinate tabber-stringers, where Multi-Ethernet masters distribute position commands to busbar welders under cleanroom constraints. Facing electrostatic discharges and 50% humidity swings, the control unit’s ESD immunity and multi-encoder fusion deliver sub-10 µm cell alignment, meeting fabricators’ yield targets above 99% by integrating torque feedback for gentle handling—thus accelerating module production scales to gigawatt capacities with embedded diagnostics curbing unplanned halts in solar’s fast-paced supply chains.

Related model recommendations

- CSB02.1B-ET-EC-NN-NN-NN-NN-NN-FW: A single-axis counterpart in the BASIC series, ideal for asymmetrical setups as a scaled-down alternative to the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW with matching Ethernet protocols for hybrid multi-axis expansions.

- CDB02.1B-PB-EC-EC-NN-NN-NN-NN-NN-FW: PROFIBUS variant for legacy fieldbus migrations, serving as a protocol-compatible replacement for the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW in brownfield upgrades while retaining dual-axis safety features.

- CSH02.1B-ET-EC-EC-NN-S4-S4-NN-NN-FW: ADVANCED model with expanded I/O slots, functioning as an upgrade from the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW for applications demanding integrated PLC functionality and higher diagnostic depth.

- CDB02.1B-ET-EC-EC-S4-S4-NN-NN-NN-FW: Safety-enhanced edition with STO extensions, recommended as a direct match for the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW in high-risk zones requiring SIL 3 compliance without hardware swaps.

- CSE02.1A-ET-EC-NN-NN-NN-NN-FW: ECONOMY single-axis unit for cost-sensitive pilots, acting as an entry-level companion to the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW in proof-of-concept phases before full dual-axis rollout.

- CDB02.1B-ET-EM-EM-NN-NN-NN-NN-NN-FW: Encoder emulation-focused variant, complementing the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW by enabling TTL output for third-party PLC integrations in mixed-vendor environments.

- HCS02.1E-ET-EC-NN-NN-NN-NN-FW: Compact single-axis drive controller for space-limited retrofits, pairing with the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW as a power stage extension in decentralized architectures.

Installation, commissioning and maintenance instructions

Installation preparation

For the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW, select a control cabinet environment adhering to EN 60204-1: ambient temperatures 0-45 °C, humidity below 95% noncondensing, and minimal exposure to conductive dust or oils to preserve dielectric integrity. Assemble tools such as a torque wrench calibrated to 0.6-0.8 Nm for screw terminals, shielded twisted-pair CAT5e cables for EtherCAT, and an ESD-safe workstation with grounding straps to avert static-induced faults. Confirm compatibility with upstream ECODRIVE power sections like HMV01 and verify 24 VDC supply stability at 2 A minimum via fused circuits. Key precautions involve de-energizing panels prior to mounting on 35 mm DIN rails, routing signal cables orthogonally to power lines for EMI mitigation, and applying ferrite clamps on Ethernet ports; enforce lockout/tagout protocols to bolster safety, while pre-loading firmware via MMC cards accelerates alignment with site-specific topologies.

Maintenance suggestions

Periodic oversight of the Bosch Rexroth CDB02.1B-ET-EC-EC-NN-NN-NN-NN-NN-FW includes bi-weekly scans of diagnostic LEDs for overheat or comms alerts, augmented by IndraWorks trend views to track axis currents and bus utilization, forestalling thermal excursions in prolonged duty cycles. Fault isolation employs the unit’s event logger—accessible via USB—for root-cause analysis, such as resolving EtherCAT timeouts by verifying cable continuity with a TDR tester, often remedied by segment resegmentation. Component refreshes, including fan replacements in ventilated enclosures, necessitate power isolation, slot extraction with release levers, and recalibration using Rexroth’s diagnostic library; maintain a spares kit with OEM cables and fuses to cap outages at 15 minutes. Annual firmware audits through the Rexrothonline portal and vibration profiling in dynamic mounts perpetuate efficacy, underpinning a service life surpassing 15 years with disciplined logging that informs predictive overhauls.

Bluecoat 800-2 ProxySG 080-02693 NEW

New Alcatel SERV 3DB02155AA

Wonderware InTouch Development 1000 Tag FS2000/9.0 New

HAAS BRUSH ROTARY CONTROL F Board 32-3051F 93-1135 NEW

IPC Alliance MX DCIC Card NEW

IPC Alliance MX ALIC Card NEW

Lot 2K Atmel ATA5743P3-TGQY ATA5743 UHF Receiver $1.25p

NORTEL NTHW08CA Mss 15000 Control Processor (cp3) Modul

ALFA LAVAL Decanter Core Controller 6121.1227-01

Nortel Multiservice Switch 15000 SHELF New Spare

Cisco Unified Communications Manager CM6.1U4-K9-UPG=

SIMRAD MC50 Marine Computer 26056010

New NIDEC SANKYO SC3150 Robot Controller 200/230vAC

CG171A-T003-05 Reflector Film UX188 etching mould USED