Description

Product Overview

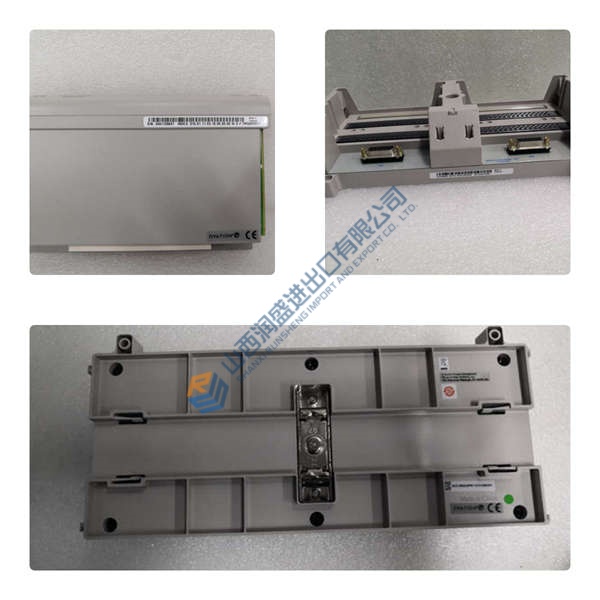

The Yaskawa CDBR-4030B is a dynamic braking module engineered by Yaskawa Electric Corporation to dissipate regen energy from drives and motors, especially in deceleration or braking events. In applications where kinetic energy is fed back into the DC bus (for example during motor deceleration or overhauling loads), CDBR-4030B acts to absorb that excess energy and prevent overvoltage trips. It is part of the Yaskawa CDBR-B family (the “B” revision of the CDBR series) and is designed for the 400 V class drives with nominal 30 kW motor capacity (≈40 HP).

Functionally, the CDBR-4030B module mounts externally to the drive and connects to the drive’s DC bus (B1/B2 terminals). Upon sensing when the DC bus voltage exceeds a threshold (its “braking start voltage”), CDBR-4030B activates its internal transistor and shunts current through an external braking resistor (LKEB series), thus converting electrical energy into heat. This alleviates stress on the drive and maintains voltage stability. Beyond simple overvoltage protection, CDBR-4030B enables shorter deceleration times, better control of braking torque, and safer operation in dynamic motion systems.

Positioned as a professional accessory for mid-size drive installations, the Yaskawa CDBR-4030B provides robust and field-proven braking support. It is suitable for use with many Yaskawa drives—especially A1000 series and other compatible models—and is intended to complement the drive’s internal braking transistor or to replace older conventional braking units (CDBR-4030, etc.). Its value lies in improving reliability, reducing faults, and ensuring stable operation under regenerative load conditions.

Application Field

The CDBR-4030B is widely used in motion control, drive systems, and industrial automation where motor deceleration, load-driven regeneration, or controlled braking is required. It is often found paired with Yaskawa VFDs (such as A1000 series, G7 series, or other compatible 400 V drives) in applications involving cranes, elevators, conveyors, extruders, hoists, presses, and other dynamic loads. The braking module helps avoid overvoltage trips and permits shorter deceleration times, thus improving cycle throughput and safety.

In factory automation and packaging lines, motors frequently reverse or stop rapidly; CDBR-4030B ensures the drive remains within safe voltage limits while absorbing regenerative energy. In large gantry systems or pick-and-place robotics, where inertia can feed back power into the drive, CDBR-4030B acts as a safeguard, enabling precise control under high dynamics.

In process industries (e.g. material handling, chemical, or steel plants) where drives decelerate heavy loads or control braking of conveyors or belt sections, CDBR-4030B is critical to reliability. Retrofitting legacy braking units with CDBR-4030B allows modernization without full system replacement. Because Yaskawa offers documentation and replacement attachments, CDBR-4030B fits well into brownfield upgrades.

Related Products

Here are some related or adjacent models and variants:

-

CDBR-4030 — the previous, conventional non-“B” revision braking unit which CDBR-4030B replaces; older form factor and possibly less optimized thermal or control features.

-

CDBR-4045B — a higher capacity braking module in the same B-series, suited for roughly 45 kW class at 400 V, offering more current capability.

-

CDBR-2022B — a lower voltage class (200 V) braking unit within the same series, useful for drives with lower voltage ratings.

-

CDBR-2110B — another variant in B-revision series for mid-range 200 V systems or legacy drives.

-

LKEB-series Braking Resistor Units (e.g. LKEB-030P, etc.) — external resistors that pair with CDBR-4030B to absorb the energy; selecting the correct resistor unit is critical for optimal braking performance.

-

CDBR-5037B, CDBR-5110B — higher voltage class braking modules (e.g. 500/600 V class) for drives that operate above 400 V, useful if migrating or scaling.

These units offer a range of voltage classes, current ratings, and power sizes. In many systems, CDBR-4030B may be swapped or paralleled with those to match load demands or voltage classes.

Product Guarantee

The CDBR-4030B is built under Yaskawa’s stringent quality assurance processes, including electrical testing, thermal cycling, and reliability validation. Each unit is warranted to be free from defects in materials and workmanship under normal operating conditions. Should any CDBR-4030B fail within the warranty period under proper use, Yaskawa (or authorized distributors) will provide repair or replacement services. Technical support is available to customers for integration, wiring, parameter setting, and troubleshooting. The guarantee encompasses continued support for firmware, documentation updates, and guidance for pairing with compatible drives and resistors. With the CDBR-4030B, we commit that its performance in absorbing regenerative energy will meet design expectations, and we back it with responsive service and replacement assurance to support mission-critical motion systems.

Lot 80 CY7C1414SV18-250BZC CY7C1414 Chips $29/each

Honeywell 24 Beam Light curtain Control FF-LS242806842

Agilent G3431-60531 FID EPC Manifold New

PELCO Esprit ES31CBW24-2W-X IOP 24X High Res PAL

VUTEk 3360 Controller Board Assy AA90206 Rev B NEW

Emerson Force PowerCore CPCI-6750/128S-400-L

Motorola STARLINE SG2000 Optical Node 415239-333-00 NEW

Alcatel 3AL97690AA LC-ESC board NEW

lot 520 iKANOS Fusiv IKF68331-A1-PB1-C chips $4/each

lot of 2500 LINEAR LTC1430CS#TR Voltage Regulator chips

Cooper Cleco STMH for TMEM TME Controller Refurbished

RICOH Z-folding Unit ZF-4000 for MP6000 MP7000 MP8000

SIEMENS SIVOLT-A-Drehstromsteller 40A 6SG2412-3CA00-Z

Endress+Hauser Turbimax CUS31-W4E New

Nortel NTN063FM S18K DDM 900 Filter 190-CY127-F1V5