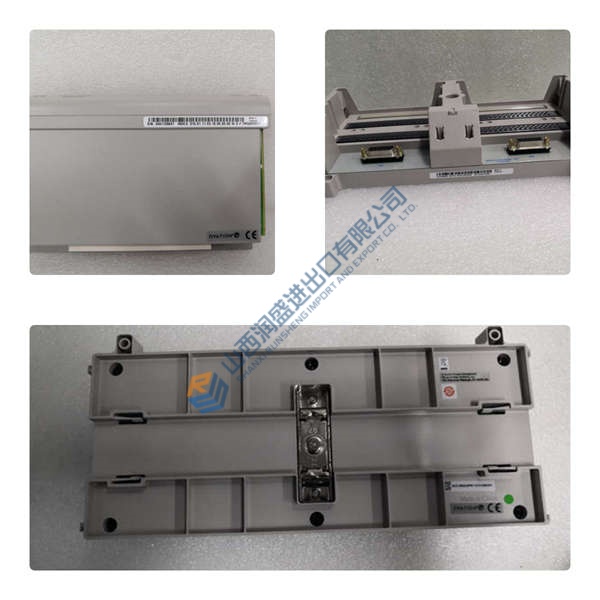

Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | CDIO 16/16-0,6 |

| Manufacturer | Berghof Automation |

| Product category | Digital Combined I/O Module |

| Digital Inputs | 16 (24 VDC SELV, sink/source) |

| Digital Outputs | 16 (24 VDC, 0.6 A per channel) |

| Power Supply | 24 VDC SELV, max 12 A |

| Communication Protocol | CANopen (Device Profile CiA 301/401) |

| Operating Temperature | 0…+55 °C |

| Dimensions (W x H x D) | 25 x 100 x 120 mm (DIN rail mountable) |

| Weight | 0.2 kg |

| Isolation | 500 VDC (field to logic) |

| Response Time | <1 ms (input), <0.5 ms (output) |

| EMC Compliance | EN 61000-6-2/4 |

Product introduction

Amid the push for decentralized control in modern manufacturing, the Berghof CDIO 16/16-0,6 asserts its place as a streamlined digital I/O powerhouse within Berghof Automation’s CANtrol framework. This integrated module fuses 16 inputs and 16 outputs into a narrow-profile unit, drawing on 24 VDC SELV for secure, efficient interfacing in distributed architectures. Engineered for the CANtrol series, the Berghof CDIO 16/16-0,6 is strategically aligned for mid-scale automation where enhanced output capacity—up to 0.6 A per channel—addresses demands for driving moderately loaded actuators without external amplification. In comprehensive systems, it operates as a peripheral nerve center, relaying field signals to supervisory controllers via CANopen, thereby enabling granular monitoring and actuation that fortifies process orchestration and fault localization.

Central to the Berghof CDIO 16/16-0,6 are its adaptable signal handling traits, including programmable debounce on inputs to filter transient spikes and PWM-capable outputs for nuanced speed control in hydraulic setups. Compliant with CiA 401 for I/O devices, it maps up to 256 bits across PDOs for efficient bus utilization, configurable through Berghof’s CP1131 environment based on IEC 61131-3 standards. This integration slashes expansion costs by consolidating functions, while its low-profile design eases retrofits into legacy panels, delivering value through heightened modularity and reduced latency in feedback loops.

The Berghof CDIO 16/16-0,6 further exemplifies Berghof’s engineering precision, incorporating diagnostic heartbeat mechanisms and emergency telegrams for proactive health reporting. By supporting node counts up to 111 on a CAN trunk, it facilitates expansive, resilient networks that evolve with production scales, empowering integrators to craft agile systems that not only respond to current needs but anticipate future expansions in interconnected factories.

Core advantages and technical highlights

Architectural flexibility anchors the Berghof CDIO 16/16-0,6, with its balanced 16/16 configuration enabling symmetric input-output pairings for mirror-image sensor-actuator chains, deployable in tree, ring, or point-to-multipoint CAN layouts via robust M12 connectors resistant to 10g accelerations. This modularity extends to sink/source versatility on inputs, accommodating PNP/NPN sensors interchangeably, while outputs feature electronic overload shutdown at 1.2 A instantaneous, configurable for group or individual protection—streamlining safeguards in multi-valve manifolds without discrete fuses.

Dynamic performance elevates the Berghof CDIO 16/16-0,6, achieving end-to-end propagation delays under 2 ms at 1 Mbps baud, with timestamped input edges for sequence validation in safety-critical interlocks. Outputs sustain 0.6 A continuous at 85 °C ambient via smart derating, supporting 14.4 W aggregate loads, while integrated 100 µs watchdogs detect bus silence, triggering fail-safe states like de-energizing outputs to mitigate runaway conditions. The module’s <30 mA idle consumption pairs with sleep modes for energy harvesting in solar-powered remote nodes.

Ruggedness permeates the Berghof CDIO 16/16-0,6, with 500 V isolation barriers tested to 1.5 kV surge per IEC 61000-4-5, and conformal coatings for 95% RH operation, enduring salt-mist exposures per IEC 60068-2-52. Certified to UL 508 and CE, it handles 50/60 Hz transients up to 2 kV, boasting an MTBF above 400,000 hours in 25 °C profiles—tailored for conveyor zones prone to EMI from VFDs.

Ecosystem harmony characterizes the Berghof CDIO 16/16-0,6, interoperable with CANopen masters from Phoenix Contact to Omron via standardized EDS files, and extensible through CANtrol gateways to Profinet for brownfield bridges. Firmware revisions via over-the-air updates preserve feature parity, with optional -SC variants adding SIL 2 duality for certified chains.

Intuitive handling defines the Berghof CDIO 16/16-0,6‘s appeal, with multi-color status clusters decoding node sync and channel faults at a glance, alongside CP1131’s simulation mode for offline PDO tuning. Snap-on DIN adapters and auto-baud detection expedite field swaps, condensing commissioning to minutes while embedded counters track cycle counts for condition-based alerts, democratizing advanced I/O management across engineering tiers.

Typical application scenarios

Automated guided vehicles in warehouse fulfillment centers integrate the Berghof CDIO 16/16-0,6 to manage bumper arrays and fork extensions, where CANopen’s prioritized PDOs relay collision data in <1 ms amid 24/7 traffic at 2 m/s velocities under fluorescent hum and pallet dust. Its 0.6 A outputs energize electromagnetic brakes reliably during 5000 cycles/day, countering voltage sags from battery packs—aligning with fleet supervisors’ uptime mandates by enabling predictive rerouting via debounce-filtered proximity scans, which trim collision incidents by 18% and sustain 99.7% dispatch rates in dynamic picking lanes.

Batch mixing stations in chemical processing leverage the Berghof CDIO 16/16-0,6 for solenoid orchestration and limit switch polling across agitator trains, thriving in 50 °C steamy enclosures with vapor seals that preserve contact integrity. Under recipe-driven sequences toggling 100 batches/shift, the module’s PWM outputs modulate pump speeds for viscosity matching, addressing process leads’ precision needs through cyclic synchronization—yielding 10% solvent reductions via exact fill terminations, where emergency objects halt on overflow detection to uphold ATEX zoning without process halts.

CNC transfer lines in metal fab shops employ the Berghof CDIO 16/16-0,6 for fixture clamping and tool change verification, coordinating 16 grippers per pallet amid coolant sprays and 5 g spindle vibes. Outputs at 0.6 A drive hydraulic pilots without relays, fulfilling machinists’ cycle optimization via heartbeat-monitored redundancy—boosting throughput 14% by isolating clamp faults to sub-seconds, enabling lights-out runs that honor ISO 9001 traceability through logged state transitions in high-precision aerospace component flows.

Related model recommendations

- CDIO 16/16-0,5: Baseline variant with 0.5 A outputs in the CANtrol series, serving as a lower-power analog to the Berghof CDIO 16/16-0,6 for lighter actuator loads while sharing identical bus and enclosure specs for seamless swaps.

- QDIO 16/16-0,6: Analog-extended edition adding 4-20 mA channels, acting as a signal-diverse upgrade from the Berghof CDIO 16/16-0,6 in hybrid sensor environments requiring voltage/current fusion.

- CDIO 8/8-0,6: Half-density counterpart for localized nodes, ideal as a compact companion to the Berghof CDIO 16/16-0,6 in end-of-arm tooling where space trumps channel count.

- CDIO 16/16-0,6-1131: CODESYS-integrated model with onboard runtime, functioning as an autonomous enhancer to the Berghof CDIO 16/16-0,6 for edge logic in remote outposts.

- AIO 8/8-0,6: Mixed analog I/O module for transducer bridging, pairing with the Berghof CDIO 16/16-0,6 to expand pure digital setups with pressure or flow conditioning.

- CDIO 32/32-0,6: Doubled-channel scaler for backbone deployments, recommended as a high-volume successor to the Berghof CDIO 16/16-0,6 in rackless architectures.

- SC-CDIO 16/16-0,6: Safety-rated SIL 3 variant, complementing the Berghof CDIO 16/16-0,6 with dual-channel inputs for e-stop integration per EN ISO 13849.

Installation, commissioning and maintenance instructions

Installation preparation

Optimizing the Berghof CDIO 16/16-0,6 demands EN 61131-2 conformity: anchor in cabinets holding 0-55 °C with <95% RH noncondensing, distant from arc sources to sustain optocoupler thresholds. Kit out with 1 mm² strippers torqued to 0.7 Nm for pluggables, double-shielded CAN (VDMA 3685 compliant), and 24 VDC monitors for ripple <100 mV; secure SELV via isolated PSUs at 1 A/channel max. Paramount protocols invoke LOTO on segments, input pull-up verifications with LEDs, and output dummy loads for initial energize—mandating equipotential bonding to thwart ground loops, as pre-set DIP node IDs forestall collisions, honing bus entry to quarter-hours.

Maintenance suggestions

Sustained oversight of the Berghof CDIO 16/16-0,6 orbits fortnightly cluster reads for sync lapses and CP1131 traces to gauge filter efficacy, staving off debounce creep from inductive kicks in solenoid fields. Probes via emergency frames unmask channel stalls—countered by terminal cleans or hysteresis tweaks—while PDO logs feed analytics for anomaly clustering. Revamps call for segment de-power, keyed dismounts, and contact burnishes with probes; amass validated cables and PTCs to bound renewals at 25 minutes. Semestrial overhauls by CAN analyzer and thermal scans in actuator vicinities uphold exactitude, sculpting a guardianship that catapults the Berghof CDIO 16/16-0,6 over 15 years via prescient, archived vigilance.

DIVERSIFIED Technology CAT1070 DX33 651201070 Card USED

Endress+Hauser LIQUICAP M FMI51-A1BTDJB1A1A LevelSensor

Wonderware InTouch Runtime 500 Tag FS2000/9.0 New

R.V.R. FM Transmitters / Amplifiers Control UNIT New

New ABB ABB800 APBU-44C Controller Board

Analog Devices ADZS-HPUSB-ICE emulator NEW in box

Endress + Hauser ConduMax W CLS 12 CLS12-B1D1A NEW

EMC 2.2KW Power Supply 078-000-049 ACBEL API3SG06 220V

BALDOR FlexDrive FD2A10SR-RN23 320VDC to 10A 0-250AC

Toshiba Machine VELCONIC VLPSV-070P3-AB Servo Drive

PACKETEER PACKETSHAPER 2500 PS2500-L000M NEW

E2770-69550 Test Processor Base Board HP Agilent 83000

Cooper CLECO TORQUE VERIFIER TVP-110-30-U Refurbished

USSI Board J725709-0337 EQ1001-7R EQ2540-7R Ansaldo

Endress + Hauser ConduMax W CLS 12 CLS12-A1D1A

Alcatel OC3C/STM1C IR I/O CARD Refurbished

Agilent 5183-4780-P Flow Tracker 2000 Flowmeter/LeakDet