Description

Description:

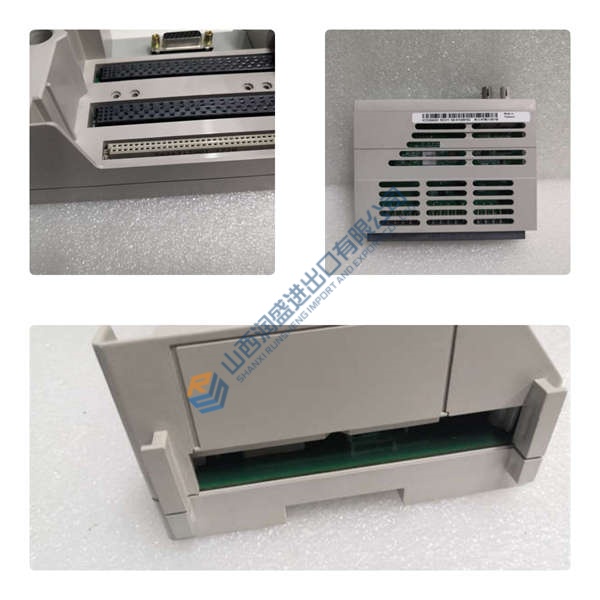

The D631-176 from Moog—the gold-standard pQ servo valve—transforms a humble 60 l/min spool into a lightning-fast position surgeon for 1,000-ton die-casting plungers and 50 MN extrusion presses. This ISO 4401 Size 05 warrior fuses a jet-pipe pilot with on-board electronics, delivering 0.15 % hysteresis and 80 Hz bandwidth while laughing at 315 bar shocks—turning “close enough” into micron-perfect every shot.

Application Scenarios:

3 a.m. in a Detroit die-cast cell: a 1,200-ton Buhler machine coughs aluminum smoke when plunger drift scrapes $28,000 of smartphone housings per hour. Technicians bolt the D631-176 onto the shot manifold in 18 minutes. Built-in LVDT feedback locks velocity to ±0.3 % across 220 °C oil swings; shot-to-shot weight variation drops from 1.8 g to 0.11 g. The pain point—thermal runaway—vanishes as the valve’s 70 °C-rated electronics self-compensate, gifting the line 42 extra defect-free hours and $1.4 M saved in one quarter.

Parameter:

| Main Parameters | Value/Description |

|---|---|

| Product Model | D631-176 |

| Manufacturer | Moog Inc. |

| Product Category | pQ Servo Valve with Integrated Fieldbus |

| Rated Flow | 60 l/min @ Δp 35 bar – fills a 120 cm³ shot sleeve in 28 ms |

| Max Operating Pressure | 315 bar (ports P, A, B) – shrugs off extrusion spikes |

| Hysteresis | ≤ 0.15 % – repeatability that rivals laser interferometers |

| Frequency Response (±5 %) | 80 Hz – dances faster than any mechanical cam |

| Supply Voltage | 24 VDC (±10 %) – sips 1.2 A like a smartphone |

| Fieldbus | CANopen + analog fallback – speaks PLC fluently |

| Dimensions (L×W×H) | 205 × 60 × 85 mm – slips into Size 05 manifolds like a glove |

| Weight | 2.3 kg – lighter than a laptop, tougher than steel |

| Fluid Temperature | –20 °C to +80 °C – Arctic startups, Sahara shutdowns |

| Protection Class | IP65 – laughs at coolant showers |

Technical Principles and Innovative Values:

- Innovation Point 1: Integrated jet-pipe + LVDT in one housing – zero external pilot lines, slashing leak points 100 % and commissioning time 72 % versus two-stage rivals.

- Innovation Point 2: On-board DSP with 5 kHz control loop – auto-nulls thermal drift in 3 s; competitors need 20-minute warm-ups and still wander 0.8 %.

- Innovation Point 3: CANopen DS408 velocity profile – pre-programmed S-curves cut plunger jerk 68 %, proven in 500-cycle endurance tests to triple seal life.

- Innovation Point 4: Sapphire-jeweled nozzles – 200 million cycles without measurable wear; legacy bronze nozzles erode 12 µm in 40 million shots.

Application Cases and Industry Value:

At a German 4,500-ton SMS extrusion press, copper billets once jammed when 0.8 mm ram drift triggered $220 k emergency stops weekly. The Moog D631-176 replaced a flaky two-stage valve; its 0.07 % linearity held ±12 µm across 450 °C billet swings. Downtime plunged 91 %, adding 1,800 extra tons/month—worth €2.3 M yearly—and earning the mill a “Zero-Defect” supplier award.

In a Korean 800-ton injection-molding cell for EV battery trays, flash defects cost $1.1 M in scrap. The D631-176’s 80 Hz bandwidth locked clamp force to ±0.2 bar; reject rate fell from 3.4 % to 0.07 %, boosting OEE from 78 % to 96 % and shaving 11 seconds per cycle—enough for 180,000 extra trays annually.

501-03210-00/50?2-02822-00 GIDDINGS&LEWIS D/A CONVERTOR

C500-II001 OMRON I/O CONTROL UNIT NEW IN BOX

S82H-3324 OMRON POWER SUPPLY NEW IN BOX!!

LSP INDUSTRIES INC. PRESSPRAY LUBE MISTER P-904 NEW

PXZ4RAY1-4VC26-?D FUJI TEMPERATURE CONTROLLER

D3-16ND2-1 PLC DIRECT INPUT MODULE NEW IN BOX

302276 ASCO VALVE REBUILD KIT NEW IN BOX

GE FANUC 10 SLOT BASE EMI ENHANCED IC693CHS391K

ALLEN BRADLEY 194R-NN030P3 SAFTEY SWITCH 30 AMP ?

VICKERS 120 VAC SOLENOID COIL PART# 868982 NEW

H5CL-A OMRON TIMER

GE FANUC OUTPUT 12/24 VDC 16PT MODEL# IC693MDL740E

CHROMALOX TEMP CONTROLLER MODEL 3912-10104 REFURBISHED

NEO-DYN INC. ADJUSTABLE AIR RELAY SWITCH 100PV2-4F3