Description

Detailed Parameter Table

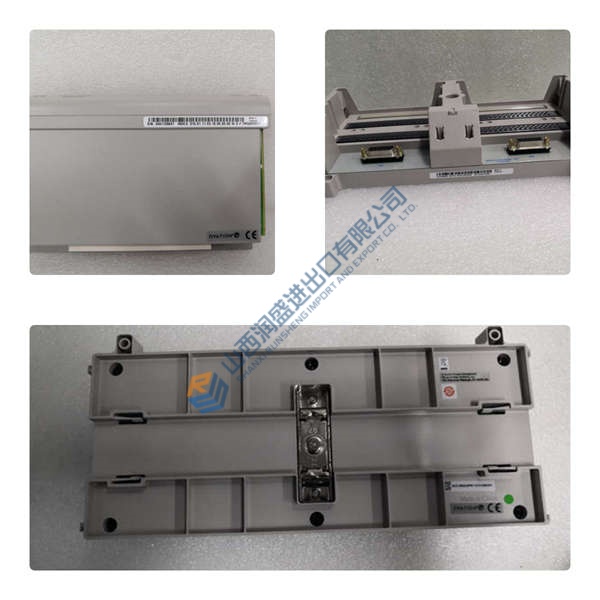

| Parameter name | Parameter value |

|---|---|

| Product model | DBU‑400 |

| Manufacturer | Reliance (Reliance Electric / Rockwell lineage) |

| Product category | Dynamic Braking Unit / Control Module |

| Maximum braking current | 400 A DC |

| Nominal DC bus voltage | Up to 750 V DC |

| Continuous braking power | Approx. 72 kW |

| Protection / enclosure | IP20, modular internal design |

| Operating temperature | 0 °C to +40 °C nominal |

| Mounting method | Vertical chassis mounting, free airflow around fins |

| Diagnostic features | Built-in diagnostic BUD card for voltage and current monitoring |

Product Introduction

The Reliance DBU‑400 is a high-capacity dynamic braking unit designed for industrial motor drive systems. It safely dissipates excess energy from the DC bus during motor deceleration or stopping events, preventing overvoltage conditions and protecting inverter components. The DBU‑400 is widely used in systems requiring frequent or heavy deceleration, such as cranes, hoists, large conveyors, and manufacturing processes with high-inertia loads.

Equipped with a built-in diagnostic BUD card, the DBU‑400 allows real-time monitoring of DC bus voltage, braking current, and fault conditions. Its modular internal design ensures easy integration into drive cabinets, providing reliable, controlled braking while maintaining the longevity and stability of the drive system.

Core Advantages and Technical Highlights

High Current Braking:

With a 400 A rating, the DBU‑400 handles high-energy deceleration events, ensuring rapid and controlled stopping of industrial motors.

Integrated Diagnostics:

The BUD card offers built-in monitoring of DC bus voltage, brake current, and fault signals, enabling predictive maintenance and reducing unexpected downtime.

PWM Braking Control:

Provides smooth, pulse-width modulated braking energy dissipation, adapting to varying load conditions for consistent performance.

Thermal Management:

Designed with appropriate thermal limits to prevent overheating, DBU‑400 allows safe operation under repeated braking cycles.

Robust Construction:

Aluminum fins and modular housing ensure durability and optimal cooling in industrial environments.

Seamless Drive Integration:

Works in coordination with inverter control modules to provide precise braking thresholds and current regulation.

Typical Application Scenarios

The DBU‑400 is suited for high-inertia and heavy-duty industrial applications:

- Cranes and hoists for energy dissipation during lowering or emergency stops.

- Large conveyor systems in manufacturing or mining environments.

- Steel, glass, and rolling mills with frequent start-stop cycles.

- Industrial presses, centrifuges, and heavy machinery requiring controlled deceleration.

- Retrofitting or adding braking capability to existing drive installations.

It enhances system safety, prevents drive overvoltage trips, and allows aggressive deceleration without compromising equipment reliability.

Related Model Recommendations

- DBU‑50, DBU‑100, DBU‑200 – Lower-current variants for smaller drive systems.

- DBU‑400‑DIS – Diagnostic variant for additional monitoring, though the standard DBU‑400 already includes the BUD card.

- BUD card – Standalone diagnostic module compatible with DBU units for monitoring voltage, current, and faults.

- Inverter control modules (BUC / BUA) – Interface modules that coordinate braking with the DBU‑400.

These models share functionality, series compatibility, or integration with DBU‑400, making them suitable alternatives, spares, or extensions.

Service and Guarantee Commitment

Reliance guarantees that each DBU‑400 is factory-tested for current handling, thermal performance, and diagnostic functionality. A warranty covers defects in materials and workmanship. Authorized service centers provide repair, recalibration, and technical support for installation, diagnostics, and maintenance. With integrated diagnostics and proven reliability, DBU‑400 ensures safe, continuous operation in demanding industrial drive applications.

ASEA BROWN BOVERI YB560103-CD/26 USPP YB560103CD26

ASEA BROWN BOVERI GNT0137100R0002 USPP GNT0137100R0002

ASEA BROWN BOVERI NDCU-22 USPP NDCU22

ASEA BROWN BOVERI 3HAB8797-1/2B USPP 3HAB879712B

ASEA BROWN BOVERI YB560103-CC USPP YB560103CC

ASEA BROWN BOVERI YYT-102C USPP YYT102C

ASEA BROWN BOVERI GCB6422C USPP GCB6422C

ASEA BROWN BOVERI 3HAA2121-2 NSPP 3HAA21212

ASEA BROWN BOVERI 3HAA3573-ACA NSPP 3HAA3573ACA

ASEA BROWN BOVERI 58096067 USPP 58096067

ASEA BROWN BOVERI YB560103-AM USPP YB560103AM

ASEA BROWN BOVERI YB560103-BE NSPP YB560103BE

ASEA BROWN BOVERI 3HAA3563-AMA NSPP 3HAA3563AMA

ASEA BROWN BOVERI DSQC116 USPP DSQC116

ASEA BROWN BOVERI RTO08358 USPP RTO08358

ASEA BROWN BOVERI EHDB-360C1 USPP EHDB360C1

ASEA BROWN BOVERI EH300C-YL11EX NSFP EH300CYL11EX