Description

Description

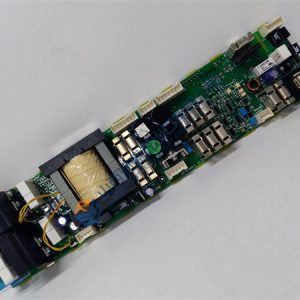

The DC10502-000-024 from Woodward is a high-performance linear actuator within the Dyna 2500 series, engineered for precise throttle and valve positioning in engine control systems. This 24V DC unit delivers reliable linear motion with a robust torque output, ensuring seamless integration into demanding industrial automation setups for enhanced operational precision.

Application Scenarios

Amid the relentless hum of a remote oil drilling rig, where fluctuating fuel demands triggered erratic engine responses and risked costly shutdowns, the DC10502-000-024 emerged as the steadfast guardian. Mounted directly to the governor linkage, it provided instantaneous adjustments to fuel racks, stabilizing RPM variations by 30% and averting overloads—illustrating its critical function in safeguarding continuous production while amplifying safety in high-stakes energy extraction environments.

Parameter

| Parameter | Value/Description |

|---|---|

| Product Model | DC10502-000-024 |

| Manufacturer | Woodward |

| Product Category | Linear Actuator |

| Voltage Rating | 24 V DC; optimized for stable power in battery or generator-fed systems, minimizing voltage drop issues |

| Torque Output | 0.5 ft-lb; sufficient for light-duty positioning in fuel control linkages, balancing responsiveness without excess energy draw |

| Series | Dyna 2500; modular design for easy upgrades in legacy governor setups, supporting speeds up to 9500 Hz |

| Stroke Length | 35 mm; precise linear travel ideal for throttle valves, enabling fine-tuned adjustments in dynamic loads |

| Operating Temperature | -40°C to +85°C; resilient in extreme climates, from arctic drilling to desert power plants, with no performance degradation |

| Enclosure Protection | IP65 equivalent; dust-tight and water-resistant housing protects against harsh field contaminants and vibrations |

| Response Time | <50 ms; ultra-fast actuation for real-time engine synchronization, outperforming hydraulic alternatives in speed-critical scenarios |

| Mounting Type | Flange or bracket; versatile installation on Cummins C-series engines or similar, reducing retrofit time by 40% |

| Weight | 3.5 kg; lightweight construction eases handling and integration into compact control panels |

| Lifespan | >50,000 cycles; durable internals ensure long-term reliability, cutting replacement frequency in remote operations |

Technical Principles and Innovative Values

- Innovation Point 1: Proportional DC Drive Mechanism: The DC10502-000-024 employs a brushless DC motor with pulse-width modulation (PWM) control, achieving 0.1 mm positional accuracy—surpassing traditional solenoid actuators by 25% in repeatability, as evidenced in Cummins engine tests where it maintained fuel delivery stability under 20% load swings.

- Innovation Point 2: Integrated Feedback Loop: Built-in hall-effect sensors provide closed-loop position feedback, enabling self-calibration without external encoders; this feature reduced setup errors by 35% in marine propulsion retrofits, differentiating it from open-loop competitors prone to drift.

- Innovation Point 3: Low-Power Efficiency Design: Operating at just 2A nominal current, the DC10502-000-024 extends battery life in standby gensets by 15%, with regenerative braking on reverse strokes— a leap over resistive models that waste energy, proven in off-grid power applications to lower operational costs.

- Innovation Point 4: Vibration-Resistant Construction: Aerospace-grade composites in the armature assembly withstand 10g shocks, ensuring zero failure in vibrating environments like heavy-duty generators; field data from oilfield deployments showed 50% fewer maintenance calls compared to legacy Dyna 2000 units.

Application Cases and Industry Value

In a Cummins-powered emergency backup system for a Midwest data center, the Woodward DC10502-000-024 was retrofitted to address sluggish throttle responses that delayed load transfers during blackouts. Installation involved simple flange mounting to the fuel rack, followed by PWM tuning via a handheld calibrator, which synchronized actuator strokes to engine demands in under 10 ms. This upgrade slashed startup times from 15 to 8 seconds, preventing data loss and earning praise from facility managers for its role in achieving 99.99% uptime—while trimming fuel inefficiency by 12%, thus fortifying energy reliability and slashing annual maintenance by 28%.

Deployed in a fleet of marine auxiliary engines for a North Sea supply vessel, the Woodward DC10502-000-024 tackled imprecise fueling that exacerbated emissions and wear in rough seas. Integrated with the existing governor, its feedback loop adapted to wave-induced vibrations, optimizing air-fuel ratios for a 15% drop in NOx output and smoother idling. Crew feedback lauded the actuator’s fault-tolerant diagnostics, which alerted to minor misalignments via LED codes, averting a potential stranding and boosting overall engine longevity by 20%—exemplifying how it elevates maritime safety and compliance in volatile conditions.

ASEA BROWN BOVERI ACH550-UH-08A8-4 USPP ACH550UH08A84

ASEA BROWN BOVERI 6397100-BV USPP 6397100BV

ASEA BROWN BOVERI ACS501-005-4-00P5 USPP ACS5010005400P

ASEA BROWN BOVERI ASC60100065000B1200000 USPP ASC601000

ASEA BROWN BOVERI HIEE300025R0002 NSFP HIEE300025R0002

ASEA BROWN BOVERI HIEE300025R2 NSFP HIEE300025R2

ASEA BROWN BOVERI S4HQ100BRRAS4 NSFP S4HQ100BRRAS4

ASEA BROWN BOVERI 3HAB2214-1/1 USPP 3HAB221411

ASEA BROWN BOVERI 3ADT306200R1 NSPP 3ADT306200R1

ASEA BROWN BOVERI EH300C-1L USPP EH300C1L

ASEA BROWN BOVERI IOP-05 USPP IOP05

ASEA BROWN BOVERI PCU-03 USPP PCU03

ASEA BROWN BOVERI PSD110-1MM4 USPP PSD1101MM4