Description

Key Technical Specifications

-

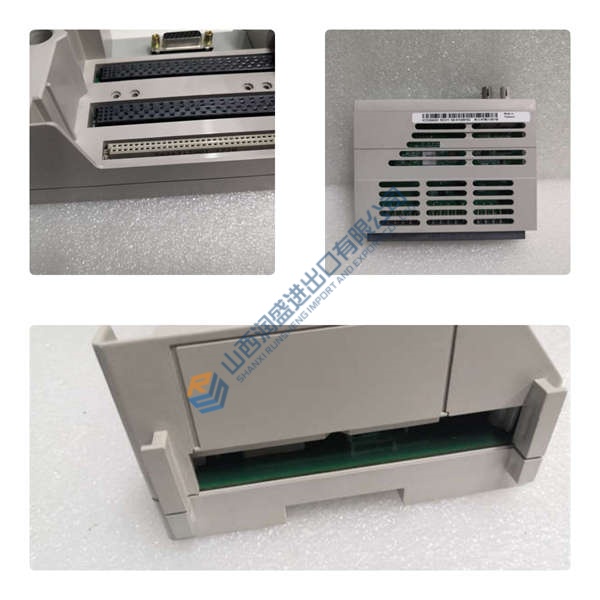

Product Model: DCC2382A 3EST125-975

-

Manufacturer: Bombardier

-

System Platform: Mitrac TC Propulsion

-

Control Voltage: 24V DC (Nominal)

-

Signal Interface: Fiber Optic / Hardwired DIN connector (configuration dependent)

-

Isolation Class: Reinforced Isolation for Traction Applications (typically >3.3kV)

-

Switching Frequency: Optimized for 800Hz – 2.5kHz traction inverter operation

-

Protection Features: Desaturation Detection (Short Circuit), Undervoltage Lockout (UVLO), Active Clamping

-

Output Power: Peak Gate Current >20A (suitable for large IHM/IHV IGBT modules)

-

Board Construction: Multi-layer FR4 with Conformal Coating (Class PC2)

-

Operating Temperature: -40°C to +85°C (Rail Class Tx)

-

Vibration Standard: Compliant with EN 61373 Category 1 Class B

-

Connector Type: Heavy-duty industrial DIN 41612

-

Feedback Signals: Collector-Emitter Voltage ($V_{CE}$), Gate Status, Temperature Monitoring

-

Application Domain: Rolling Stock Propulsion (Metro, EMU, Electric Locomotives)

Technical Architecture & Functional Positioning

Architecture Analysis

The DCC2382A serves as the critical interface layer between the digital processing domain (Traction Control Unit – TCU) and the high-power silicon domain (IGBT Power Modules) within a railway propulsion converter. In the Mitrac system architecture, this module acts as a decentralized gate drive unit (GDU) or phase control interface. It is designed to convert low-power logic command signals into the high-current, isolated gate pulses required to switch large IGBT modules (often 1200V, 1700V, or 3300V class) that drive the traction motors.

Technologically, the module employs advanced galvanic isolation—typically using high-frequency transformers for power and opto-couplers or fiber optics for signal transmission—to bridge the gap between the low-voltage control electronics and the high-voltage DC link (catenary potential). A key architectural feature is the integration of local protection logic. Instead of relying solely on the central processor, the DCC2382A includes hardware-level desaturation detection. If an IGBT short circuit occurs, the board reacts in microseconds to shut down the gate pulse softly, preventing the catastrophic voltage spikes ($di/dt$) that would otherwise destroy the power semiconductor.

From an engineering perspective, this decentralized design solves the problem of electromagnetic interference (EMI) in high-power traction environments. By placing the driver stage physically close to the IGBT or acting as a robust buffer, the module minimizes gate loop inductance, ensuring clean switching waveforms and reducing switching losses. This directly contributes to the thermal efficiency and reliability of the entire propulsion chain, which is paramount for rolling stock operating in harsh transit environments.

Typical Application Scenarios

-

Metro and Mass Transit: utilized in the Variable Voltage Variable Frequency (VVVF) inverters driving induction or permanent magnet motors on subway cars.

-

Electric Multiple Units (EMUs): Controls the line converter (four-quadrant chopper) or motor inverter phases in regional commuter trains.

-

Locomotive Modernization: Serves as a replacement component for legacy GTO-to-IGBT upgrades in heavy-haul electric locomotives.

-

Auxiliary Power Units (APU): Managing power conversion for on-board hotel loads (HVAC, lighting) in older Bombardier rolling stock configurations.

Quality Standards & Testing Procedures

Quality Philosophy

In the rail industry, component reliability is synonymous with passenger safety and schedule adherence. A failure in a traction control card like the DCC2382A can lead to a stranded train, blocking active lines and incurring significant penalties. We recognize that these legacy parts often operate past their original design life; therefore, our testing protocol goes beyond simple “power-on” checks. We adhere to a rigorous refurbishment and verification SOP designed to replicate the mechanical and electrical stress of a moving train environment.

Standardized Testing Protocol (SOP)

Visual Inspection & Chemical Cleaning

We utilize high-magnification optical inspection to identify micro-cracks in solder joints, particularly around heavy connectors and transformers, which are prone to vibration fatigue. The board is cleaned using an automated ultrasonic wash with specialized electronics-safe solvents to remove conductive brake dust and carbon buildup common in rail environments, followed by re-application of conformal coating where necessary.

Component Level Verification

Electrolytic capacitors—the components most prone to aging—are tested for Equivalent Series Resistance (ESR) and capacitance. Opto-couplers are tested for current transfer ratio (CTR) degradation. Any components showing drift from original manufacturing tolerances are preemptively replaced with automotive-grade or rail-grade equivalents.

Dynamic Load & Functional Testing

-

Gate Pulse Characterization: We connect the module to a simulated IGBT load (gate capacitance equivalent). Using a high-bandwidth oscilloscope, we verify the rise time ($t_r$), fall time ($t_f$), and gate voltage levels ($+15V / -8V$ or similar) to ensure they meet the strict requirements for efficient switching.

-

Protection Logic Verification: We simulate fault conditions, such as an IGBT desaturation event (short circuit simulation), to verify that the DCC2382A triggers its “Soft Turn-Off” mechanism and asserts the fault feedback signal to the controller within the specified microsecond window.

-

Thermal Soak: The unit undergoes operation at elevated temperatures (typically 60°C) for 24 hours to screen for early life failures or thermally intermittent solder joints.

Firmware & Revision Check

We verify the hardware revision level (e.g., Rev A vs. Rev C) and any onboard PLD/FPGA logic configurations against the specific 3EST125-975 BOM to ensure plug-and-play compatibility with the specific generation of Mitrac software.

Compatibility & Installation Maintenance Guide

Engineering Notes

Replacing a drive control card in a traction converter requires strict adherence to safety and technical protocols. The most common cause of post-replacement failure is not the card itself, but the condition of the peripheral connections and the high-voltage environment.

Pre-Replacement Checklist

-

DC Link Discharge: Critical Safety Warning: Ensure the traction container’s DC Link capacitors are fully discharged and verified with a high-voltage probe before accessing the card. Residual voltage can be lethal.

-

Part Number Match: Bombardier parts often look identical but have different suffix codes (e.g., -975 vs. -976). These differences often relate to threshold voltages or timing constants specific to the IGBT modules used (e.g., Infineon vs. Mitsubishi). Installing a mismatched suffix can lead to inefficient switching or nuisance tripping.

-

Conformal Coating Check: Ensure the replacement board has intact conformal coating. If the installation environment is humid or dusty (common in underframe inverters), verify the coating covers all sensitive pins to prevent tracking faults.

-

Connector Integrity: Inspect the backplane or cable harness connector. In older trains, the female pins on the harness often lose elasticity (contact pressure), leading to intermittent signal loss during track vibrations.

Electrostatic Discharge (ESD) Protection

The DCC2382A contains high-speed CMOS logic and sensitive analog comparators. It must be handled at an ESD-safe workstation. Do not touch the gold-plated connector fingers or component leads. Transport the board only in metalized shielding bags.

Installation & Commissioning

-

Visual Alignment: When inserting the card into the rack or mounting it to the phase module, ensure zero mechanical stress. Forcing the card can crack the multi-layer ceramic capacitors (MLCCs).

-

Gate Emitter Wiring: If the board uses discrete wiring to the IGBT, ensure twisted pair cables are used and routed away from high-current busbars to prevent noise induction.

-

Initial Power Up: Apply low-voltage control power (24V) first. Verify no fault LEDs are active before applying high voltage (Line Voltage).

Our Service & Commitment

We provide specialized support for the lifecycle extension of rolling stock assets. We understand that for many operators, the DCC2382A is part of a legacy fleet where OEM support may be limited or lead times are excessive. Our team of rail automation engineers has extensive experience with the Bombardier Mitrac architecture.

We do not just “sell parts”; we provide technical assurance. Every module supplied is a genuine OEM component that has been rigorously refurbished and tested. We guarantee that the isolation barriers are intact and that the drive characteristics match the original factory specifications.

We offer a comprehensive 12-month warranty on all rail control modules. If a unit fails to perform within the warranty period, we offer immediate replacement or expedited repair services. Our global logistics network is optimized for critical spare parts, ensuring that whether your depot is in Europe, Asia, or the Americas, we can deliver the components you need to get your rolling stock back on the rails.

Global Supply & Technical Support

Global Railway Component Specialist

RUNSHENG Automation is a trusted partner for railway operators and maintenance (MRO) providers globally. We specialize in the sourcing and refurbishment of hard-to-find traction control components for Bombardier, Alstom, Siemens, and ABB propulsion systems.

Strategic Inventory & Sourcing

We maintain a strategic inventory of legacy Mitrac system components to support fleets that are 10-20+ years old. Our sourcing network extends across major European and Asian rail hubs, allowing us to secure surplus stock and verified decommissioned units that are no longer available directly from the OEM.

Professional Export & Logistics

We are experienced in the complex logistics of international rail parts supply. We handle all necessary export documentation, customs classifications, and secure packaging requirements. For urgent “Line Down” situations (AOG equivalent in rail), we offer expedited air freight options to major transit hubs worldwide.

Related Products & System Components

Key components working in conjunction with the DCC2382A within the Mitrac propulsion system include:

-

Bombardier TCU (Traction Control Unit): The main processor rack (often VME or CPCI based) that calculates torque demands and sends switching patterns to the DCC module.

-

IGBT Power Modules: High-voltage semiconductor switches (e.g., 3.3kV / 1200A) from manufacturers like Infineon or Mitsubishi, which are directly driven by the DCC2382A.

-

DC Link Capacitor Bank: Provides the stable DC voltage source for the inverter; the DCC module monitors this voltage for protection.

-

Current Transducers (LEM Sensors): Measure the output phase current and return feedback to the control system to close the torque control loop.

-

Gate Adapter Board: A small intermediate PCB often mounted directly on the IGBT module, acting as the physical mating point for the signals from the DCC2382A.

ASEA BROWN BOVERI 1911RA001400000STD USPP 1911RA0014000

ASEA BROWN BOVERI 1912RA001100000STD USPP 1912RA0011000

ASEA BROWN BOVERI 1913JA002100000 USPP 1913JA002100000

ASEA BROWN BOVERI 1953RAA01100090STD USPP 1953RAA011000

ASEA BROWN BOVERI 2668180-586 NSPP 2668180586

ASEA BROWN BOVERI YB161102-CB USPP YB161102CB

ASEA BROWN BOVERI 57120001-E USPP 57120001E

ASEA BROWN BOVERI 126620-004 USPP 126620004

ASEA BROWN BOVERI YT212001-BG USPP YT212001BG

ASEA BROWN BOVERI YT212001-BR-YBKA70-15 USPP YT212001BR

ASEA BROWN BOVERI 083892-001 NSFP 083892001

ASEA BROWN BOVERI ACH401600532-ACE0000 NSFP ACH40160053

ASEA BROWN BOVERI 58908011 USPP 58908011

ASEA BROWN BOVERI 6252NA10700A NSPP 6252NA10700A

ASEA BROWN BOVERI YT204001-FD USPP YT204001FD

ASEA BROWN BOVERI GNT0153800R0001 USPP GNT0153800R0001

ASEA BROWN BOVERI 57510001-AA USPP 57510001AA

ASEA BROWN BOVERI DSCA-114 USPP DSCA114

ASEA BROWN BOVERI 57360001-EB USPP 57360001EB

ASEA BROWN BOVERI ACH550-UH-031A-2 USPP ACH550UH031A2

ASEA BROWN BOVERI YB560103-BL/2 USPP YB560103BL2