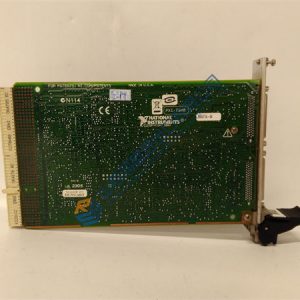

Description

- Product Model: IS215ACLEH1BC

- Manufacturer: GE

- System Platform: Mark VI Speedtronic / Innovation Series

- Processor Type: Fourth-generation DX4-100 486 compatible processor running at 100 MHz core speed

- Cache Memory: 16 KB internal L1 cache

- Bus Speed: 33 MHz PCI bus rate at 33 MT/s

- DRAM Memory: 8 MB onboard for application execution and data buffering

- Ethernet Interface: 10BaseT Ethernet port (RJ-45) for network communication

- Additional Interfaces: Dual COM ports (serial), dual ISBus connectors for inter-module communication

- Operating Temperature Range: -30°C to +65°C, suitable for enclosed industrial cabinets

- Humidity Tolerance: 5% to 95% non-condensing, with protective conformal coating

- Power Supply: 5 V DC primary from rack backplane, with low power consumption design

- LED Indicators: Four function LEDs, eight status LEDs, four ISBus LEDs on front faceplate

- Reset Mechanism: Single front-panel reset switch for module initialization

- Certification Standards: CE compliant, UL recognized for industrial control equipment, meets IEEE and ANSI standards for turbine controls

- Mean Time Between Failures (MTBF): > 100,000 hours in typical continuous operation

- Core Voltage Tolerance: ±0.3 V, ensuring stable processor performance under varying load conditions

Technical Architecture & Functional Positioning

The IS215ACLEH1BC occupies the control core position in GE Mark VI systems, acting as the primary microprocessor host for executing turbine application logic, sequencing, and protective algorithms. Situated at the supervisory and control layer, it interfaces directly with I/O packs via the ISBus (Innovation Series Bus) and coordinates data exchange over Ethernet and serial links to HMI, SCADA, or other networked devices. This central role enables it to process complex control strategies while maintaining deterministic response times critical for gas/steam turbine speed governing, load control, and fault protection.

The module employs a robust 486-class processor architecture with integrated PCI controller for managing peripheral I/O and communication traffic. Key technologies include high-speed internal caching for reduced latency in loop execution, redundant pathway support through dual ISBus connectors, and comprehensive LED diagnostics for real-time health monitoring. These features solve fundamental engineering problems in turbine controls: ensuring reliable execution of safety-critical code under high computational loads, minimizing communication bottlenecks in distributed systems, and providing immediate visual fault indication to reduce troubleshooting time during outages.

The design prioritizes modularity, allowing the ACL to operate in both simplex and redundant configurations while supporting online replacement in TMR setups. Its firmware environment facilitates loading of custom application code via standard GE tools, addressing scalability needs in evolving plant operations where control logic updates must occur without extended downtime.

Typical Application Scenarios

- Deployed as the central processor in Mark VI-controlled gas turbines for executing core sequencing, governor, and protection logic during startup, synchronization, and steady-state operation.

- Integrated in combined-cycle power plants using Innovation Series drives, coordinating excitation and governor functions for optimal plant performance.

- Serves as a replacement or upgrade module in legacy Mark VI installations, maintaining compatibility with existing I/O and network infrastructure.

- Utilized in industrial process drives and compressor trains for high-reliability control in oil & gas facilities, ensuring stable operation under variable loads.

- Applied in retrofit projects transitioning from older Speedtronic platforms, enhancing processing power and diagnostic capabilities without full system replacement.

Quality Standards & Testing Procedures

Control processors like the IS215ACLEH1BC form the computational backbone of turbine systems—processor faults can halt execution of protective algorithms or disrupt communication, leading to forced outages or safety risks. We enforce a comprehensive, application-specific testing regime that aligns with GE’s rigorous standards to verify full operational integrity before shipment.

Visual Inspection & Cleaning

Modules are examined for processor socket integrity, capacitor condition, solder joint quality, and any signs of thermal stress or contamination. Rejected if defects found. Cleaning uses ESD-safe solvents to clear dust and residues from connectors and board surfaces.

Live Testing

Boards are powered in a Mark VI simulation rack for ≥24 hours continuous run, monitoring processor temperature, voltage rails, bus activity, and LED status under nominal and stress conditions to identify intermittent issues.

Functional Verification

- Processor & Memory Testing: Full boot sequence validation, memory integrity checks, and cache performance verification using diagnostic loops.

- Communication Diagnostics: Ethernet link tests with packet transmission/reception, ISBus loopback verification, and serial port echo testing for zero-error data integrity.

- LED & Reset Functionality: All front-panel LEDs cycled through states; reset switch tested for reliable module reinitialization without hanging.

- Load Simulation: Application code emulation run to confirm execution stability, interrupt handling, and response under simulated control loads.

GE Fanuc IC697CPU781E IC697CPU781 NEW

GE Fanuc IC752WTCSS2-AC IC752WTCSS2 IC752

GE FANUC SERVO MOTOR A06B-0041-B605 #S042 30/3000 NEW

GE Fanuc 531X132APGACG1 531X132APG 531X

GE Fanuc SERVO AMP A06B-6107-H001 A16B-3200-0610 NEW

GE Fanuc A16B-2201-0791/03B A16B-2201-0791 VISION NEW

GE Fanuc A06B-6078-H311 #H500 AC SERVO AMP

GE FANUC DS3800NMEA1G1E DS3800NMEA1G DS3800NME DS3800

GE FANUC DS3800NMEA1HEF DS3800NMEA1 DS3800NME DS3800

GE FANUC IC600LX616 NSFP IC600LX616

GE FANUC 44A399751-G01 USPP 44A399751G01

NEW GE Fanuc AC Servo Motor A06B-0572-B088 A06B0572B088

GE FANUC IC800SSI216D2 USPP IC800SSI216D2

GE FANUC 6KP1143075X9B1 USPP 6KP1143075X9B1

GE FANUC DS3800HSQD1J1G DS3800HSQD1J DS3800HS DS3800

GE FANUC IC3600STKK1 USPP IC3600STKK1

GE FANUC IC752DPA262 USPP IC752DPA262

GE Fanuc SERVO AMPLIFIER A06B-6058-H101 A16B-1100-0300