Description

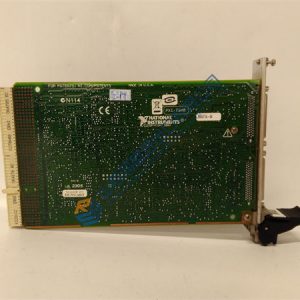

- Product Model: IS215VCMIH2BEE

- Manufacturer: GE

- System Platform: GE Mark VIe DCS

- Input Voltage: 24V DC (Nominal)

- Input Current: 200 mA (Typical)

- Power Consumption: 5W

- Signal Type: Vibration (Analog and Digital Inputs)

- I/O Channels: 8 Vibration Channels, 4 Analog Outputs

- Communication Protocols: Modbus RTU, Ethernet TCP/IP, GE Proprietary

- Response Time: < 10 ms (for Digital Inputs)

- Operating Temperature: -20°C to +70°C

- EMC Compliance: CE, UL, IEC 61000-6-2, IEC 61000-6-4

- ATEX Certification: Ex ia IIC T4 (for hazardous environments)

- Vibration Measurement Range: 0.1 Hz to 10 kHz

- Accuracy: ±0.1% of full scale for vibration signal

- Mounting: Rack-mounted, 3U size

- Isolation Voltage: 500V RMS

- Humidity Range: 5% to 95% RH (Non-condensing)

Technical Architecture & Functional Positioning

Architecture Analysis

The IS215VCMIH2BEE serves as an essential vibration control and monitoring module in the GE Mark VIe DCS. Positioned in the field I/O layer, it collects, processes, and transmits vibration signals from industrial machinery, particularly turbines and compressors, to the control system. This functionality is critical for predictive maintenance and real-time system health monitoring.

- System Role: The module interfaces directly with field sensors to measure vibration in rotating machinery. It processes the signals in real-time and transmits this data to the central control system for monitoring and analysis.

- Core Technology: The IS215VCMIH2BEE utilizes high-precision signal conditioning, ensuring accurate data acquisition even in environments with high electromagnetic interference (EMI). It also incorporates built-in isolation to protect against electrical surges and spikes, ensuring the integrity of sensor data.

- Engineering Value: Vibration data is crucial for early detection of faults such as imbalance, misalignment, or bearing wear in rotating machinery. The IS215VCMIH2BEE enhances system reliability by ensuring that real-time vibration data is accurately processed and monitored, allowing for predictive maintenance strategies and preventing unplanned downtime.

Typical Application Scenarios

- Applied in power generation plants for monitoring the vibration of turbine units and enabling predictive maintenance.

- Used in chemical and petrochemical industries for real-time vibration analysis of critical rotating equipment.

- Serves as an OEM replacement module for older systems, providing improved performance and compatibility with modern GE Mark VIe systems.

- Utilized in manufacturing for continuous monitoring of motors, pumps, and compressors, ensuring operational stability and reducing maintenance costs.

GE FANUC CONTROL PANEL MONITOR/KEYBOARD/TAPE READER

GE FANUC A06B-0502-B005#7008 SERVO

GE Fanuc IC600BF948P Comm Control Rev P Used & Repaired

One-day shipping available

GE Fanuc IC697MEM732 MODULE

GE Fanuc A02B-0118-B006 POWERMATE

GE FANUC AC SERVO MOTOR A06B-0142-B075# 7008

Enlarge

GE FANUC AC SERVO MOTOR A06B-0142-B175

Enlarge

IC300OCS351H-07 GE FANUC OPERATOR CONTROL STATION – NIB

One-day shipping available

GE FANUC SERVO MOTOR A06B-0147-B176 #7075 22/2000

GE Fanuc IC660BBA105K Analog Current Source Module

GE Fanuc A06B-6066-H008 SERVO AMPLIFIER

GE FANUC A06B-0128-B175#7000 SERVO

Ge FANUC A05B-2452-C473 A20B-1007-0800 NEW

Ge FANUC A05B-2401-C412 A20B-1007-0490 NEW

NEW ? GE FANUC SERVO AMPLIFIER A06B 6058 H323 AMP CNC

Expedited shipping available

GE FANUC DRIVE 90-70 DLAN INTERFACE IC697BEM763F MODULE