Description

- Product Model: IS215WEPAH2BA

- Manufacturer: GE

- System Platform: Mark VIe Wind Turbine Control

- Power Supply Voltage: 24 V DC nominal (tolerance typically 18-32 V DC), accommodating nacelle voltage fluctuations

- Power Consumption: Approximately 20-50 W, dependent on actuator load and drive demands

- Operating Temperature Range: -30°C to +65°C, engineered for nacelle or hub environments with thermal cycling

- Humidity Tolerance: Up to 95% non-condensing, featuring conformal coating for moisture and contaminant resistance

- Actuator Compatibility: Optimized for 30/40 Nm pitch motors (with variants supporting 20 Nm configurations)

- Communication Interfaces: Non-CANbus design, relying on analog and discrete signals for pitch master integration

- Analog Inputs: Differential channels for position encoder feedback, current sense, and command reception

- Servo Amplification: Integrated power stage for direct actuator drive, with current limiting and protection

- Signal Conditioning: Onboard isolation, filtering, and amplification to counter EMI from hub electronics

- MTBF: High-availability architecture typical of Mark VIe pitch modules (>150,000 hours in cyclic operation)

- Certifications: Aligned with IEC 61400 wind standards (as applicable), CE marking, and industrial environmental compliance

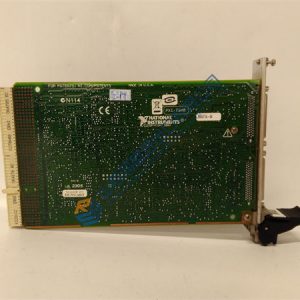

- Dimensions: Compact PCB suitable for pitch cabinet or hub mounting (typical series form factor)

- Weight: Lightweight construction (under 2 kg), supporting safe handling in elevated access scenarios

- Protection Features: Conformal-coated for vibration, dust, and humidity endurance in rotating hub applications

Technical Architecture & Functional Positioning

The IS215WEPAH2BA operates as a pitch axis servo controller (WEPA – Wind Energy Pitch Axis, non-CANbus variant) in the Mark VIe wind turbine control hierarchy. Positioned in the pitch drive subsystem—typically within the hub or associated cabinet—it translates pitch commands from the central controller into precise actuator motion for individual blade adjustment. This board focuses on closed-loop servo control, processing analog feedback from position sensors and current transducers to regulate blade angle for optimal aerodynamics, power regulation, and emergency feathering.

The architecture employs analog-centric signal paths with integrated power amplification, eliminating CANbus dependency for simpler, deterministic interfaces in certain turbine configurations. Key circuits include differential input conditioning for noise rejection, proportional-integral control elements (implemented in hardware/firmware), and robust output stages capable of driving 30/40 Nm electric or hydraulic pitch actuators. Protection features such as overcurrent shutdown and thermal monitoring ensure safe operation during rapid pitch changes or fault conditions.

This non-CANbus approach solves engineering needs in legacy or specific wind fleets where simpler wiring and lower protocol overhead are preferred, while still delivering fast response times essential for load alleviation and overspeed prevention. In variable-pitch turbines, the board’s precision contributes to reduced structural fatigue, improved energy yield, and compliance with grid code requirements during transients.

Typical Application Scenarios

- Blade pitch regulation in GE wind turbines (1-3+ MW range) for power optimization, stall/pitch-to-feather control, and fatigue load reduction.

- Emergency pitch actuation in DFIG systems during grid disturbances or high-wind events to prevent rotor overspeed.

- Replacement component in Mark VIe-equipped wind farms maintaining non-CANbus pitch interfaces during repairs or upgrades.

- Hub-level servo drive in variable-pitch configurations requiring reliable analog feedback and direct actuator control.

- Onshore installations with demanding environmental exposure, leveraging conformal protection for sustained reliability.

Honda EGA NSR-TB-1REPAIR TEACH PENDANT NSR-TB-1-1

ABB ASEA PC Board YPR 104 2668 184-736/1 2668184-736/1

Rexroth Prop Amplifier VT3006 VT3006-S35-R5 VT3006S35R5

NSK Precision Ball Screw W3207G-89P-C5Z 30″ 1″ dia NEW

Fisher DPR900X1-A5 DPR 900 Controller DPR900

Fisher Rosemount 0444rl1u1c2na temperaure 0444rl1u1

FIFE CONTROLLER CSP-01-MVRC CSP-01R CSP01MVRC

New OMRON SYSDRIVE Inverter 3G3MV-C2001 .3 kva

Total Control QuickPanel QPL21100C2P A QPI-ABD-201

Leesona Saftronics Drive 1hp 1 hp 968-1492-52 CA 246-2

Westinghouse Sz Size 5 GCA 530 2050A15G16 2045A41G01

Honeywell Chart Recorder AR15ADN2011 120v 24hr NEW

NEW TOYODA MACHINE WORKS MC256-C MC256C MC256 C NEW

Allen Bradley Panelview 550 2711-K5A1 2711K5A1 Ser B

Dynax Robot Controller TT1-3 TT13 TTT1 3 24V

ABB ASEA YPH 105 YPH105 YPH 105A YPH105A YT204001-0Y/2

Telemecanique Altivar 5 Drive ATV45U22N 3hp 3 hp

Honeywell ST3000 Smart Transmitter STA140

New Cutler Hammer CB00107 CB00107-6030 PCP 500V M6

Gould Modicon 115vac Isolated Output B246-501 B246501

FISHER ROSEMOUNT 0444RL2U1A2E5 0444RL2U1A2E5

ABB ASEA Board YPR 104 2668 184-736/1 2668184-736/1