Description

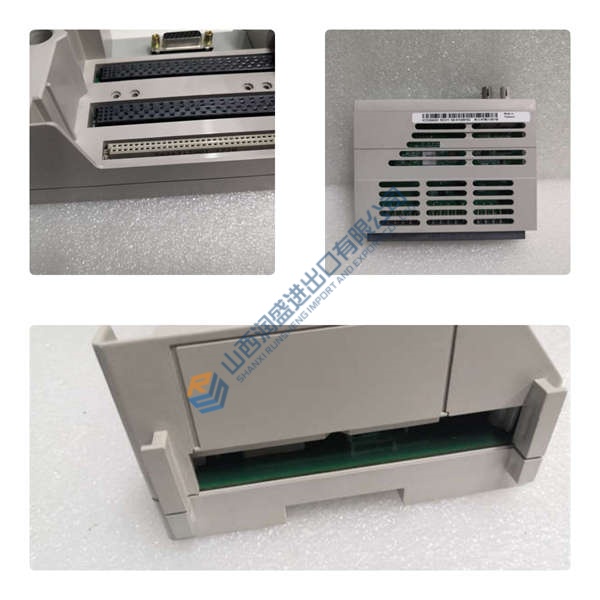

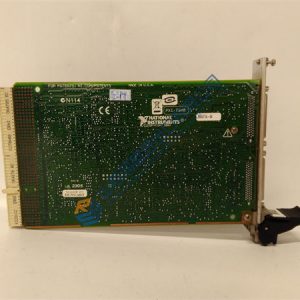

- Product Model: IS220PRTDH1B

- Manufacturer: GE (General Electric)

- System Platform: Mark VIe Distributed Control System

- Channels: 8 RTD input channels

- Input Type: RTD (Resistance Temperature Detector)

- Supported RTD Types: 100Ω Platinum RTD (PT100)

- Input Range: -200°C to +850°C

- Input Resistance: 100Ω ±0.1%

- Input Accuracy: ±0.1°C

- Communication Protocol: IONet Ethernet communication for seamless integration with Mark VIe

- Power Supply Voltage: 24V DC

- Operating Temperature Range: -30°C to +65°C

- Certifications: UL, CE

- Mounting Style: Rack-mounted

- Power Consumption: 0.6A maximum at 24V DC

Technical Architecture & Functional Positioning

The IS220PRTDH1B is an RTD input module that provides precise temperature measurement for various industrial control applications. It is a key component in the Mark VIe system for monitoring and controlling temperature-sensitive processes, such as turbine operations in power plants, refineries, and industrial automation systems.

Key Features:

- Precision Temperature Measurement: The module supports 8 RTD input channels with precise temperature measurement, offering high accuracy of ±0.1°C across a wide temperature range from -200°C to +850°C. This ensures reliable performance in critical applications requiring precise thermal management.

- RTD Compatibility: The IS220PRTDH1B is designed for use with 100Ω Platinum RTDs (PT100), which are widely used for industrial temperature sensing due to their stable and repeatable performance.

- Seamless Integration: The module integrates seamlessly with Mark VIe via IONet Ethernet communication, enabling quick system response times and efficient data exchange.

Positioned in the I/O layer of the control system, this module enables accurate temperature monitoring and feedback to the central control system, ensuring that processes stay within their desired temperature limits.

Typical Application Scenarios

- Turbine Temperature Monitoring: Used in Mark VIe turbine control systems to monitor key temperatures in turbines, generators, and compressors, ensuring safe and efficient operation.

- Industrial Process Control: Applied in chemical and petrochemical industries for continuous temperature monitoring in critical processes, such as reactors and heat exchangers.

- HVAC and Climate Control Systems: Utilized in temperature monitoring within HVAC systems, particularly in large facilities or in environments with strict temperature control requirements.

- OEM-Compatible Replacements: Ideal for upgrading legacy systems with high-accuracy temperature sensing capabilities.

Caldwell Strong Bac Crane Lift Fork 15000lbs 96S-7.5-60

RELIANCE 25C60 25 HP 25HP 460VAC IN 500VDC OUT DC DRIVE

Honeywell MiniTrend V5 Recorder TVMI TVMI-6F-00 NEW

GE FLEX-A-PLUG SB365RGR BUSWAY PLUG 400A 400 A AMP NEW

ALLEN BRADLEY DATAMYTE 953-07 953 07 95307 CL-M1000

Siemens Simatic IPC RI 45 RI45 PIII 6ES7643-4DC20-0CA1

Staming Press Control Compumotor RP240 PMC6270 C200H

SERV-I-QUIP 0915 REFRIGERANT RECLAMATION SYSTEM

WEMCO Torque Flow Pump C 1200 GPM 530 RPM

SPENCER TUBULAR BAG SEPARATOR COLLECTOR 3000 CFM 100HP

GRACO KING AIR MOTOR 245111 245-111 A07A 100 PSI NEW

Mueller Accu-Therm Plate Heat Exchanger AT402 C-20

Square D Mini-Break Load Interrupter HVMH-305200 200 A

NEW MEYER AND SONS ROTARY AIRLOCK 10X10 HDX 253036-10

SIEMENS SIMOREG INTERFACE CARD A1-116-100-505 IS05

ALLEN BRADLEY Armature Spares 2361-SPG03A C 185442 NEW

Schneider Modicon NW-RR85-001 NWRR85001 Repeater NIB

Reliance Rectifier Thyristor 86466-74T 86466 74T REMAN

GE FVK465RT 400A 400 A AMP 480V 3 PH 4W BUSWAY SWITCH

SIEMENS 6 RA 2674-6MV30-ZA14 D200/175 COMPACT CONVERTER

SIEMENS SIMATIC S7 PLC CPU 6ES7 318-2AJ00-0AB0

COFFING 5 TON CHAIN HOIST 230/460 3PH WITH TROLLEY