Description

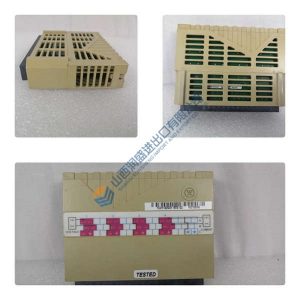

1. Key Performance Indicators

- Rated output power: 2.8 kW

- Voltage range: 230–480 V AC

- Maximum continuous current: 8.5 A

- Control mode: Closed-loop speed and position control

- Encoder interface: Incremental / Absolute compatible

- Communication protocol: CANopen, EtherCAT

- Open-loop / Closed-loop switchable

- Overload protection: 150% rated current for 60 seconds

- Operating temperature: 0–55°C

- Storage temperature: -25–70°C

- Protection class: IP20

- Shock and vibration resistance: IEC 60068 standard

2. Operational Mechanism and System Value

This module functions as a high-performance servo drive in Rexroth DCS or PLC architectures, converting electrical energy into precise mechanical motion. It delivers closed-loop torque and speed control, ensuring stable system response and optimized energy usage. Real-time feedback enables predictive maintenance and operational efficiency, while its integration into redundant circuits and safety stop logic reduces overall plant downtime risk.

3. Downtime Risks and Fault Forecasting

- Failure to replace this unit may result in reduced production line accuracy, compromising product quality and throughput.

- Market prevalence of refurbished units increases secondary downtime risk and hidden maintenance costs.

- Continuous operation under high load with aging units increases thermal degradation risk, potentially causing motor overload or control failure.

4. Core Competitiveness Analysis

The HCS01.1E-W0028-A03-A-CC-EC-ET-L3-NN-FW servo module is engineered for industrial environments demanding high reliability and precision. Its advanced PCB layout, combined with industrial-grade MOSFETs and enhanced cooling architecture, ensures continuous operation over a decade under rated load conditions. The integrated absolute encoder interface provides precise position feedback, reducing cumulative motion errors. Encapsulated power electronics and reinforced connectors improve resistance against EMI, vibration, and transient voltage spikes. Compared to competitors, the module’s firmware is optimized for deterministic response, minimizing latency in closed-loop control. Material selection, including high-grade thermal composites and anti-corrosion coatings, supports durability in humid or dusty environments. Collectively, these design choices establish the HCS01 series as a cornerstone for long-term industrial automation stability, reducing total cost of ownership and reinforcing predictable asset performance.

NITTAN TECHNO ACM-20 CRIMPING MACHINE 20 TON

NITTAN TECHNO ACM-20 CRIMPING MACHINE

NITTAN TECHNO ACM-20 CRIMPING PRESS 20T

JEEFREY P804988B STEEL WELDED CHAIN 16FT

FOX BORO 2AT-CAL SYSTEM CALIBRATOR

CHAS. S. LEWIS 24-90020560 VOLUTE

73-00027430 ROTATING ELEMENT FAN

73-003000070 FAN WHEEL Propellent

DURIRON EV-1 AQUA CARE FILTRATION SYSTEM

78-68021235 GEAR

Vibco SCR-400 Vibratory Table

M&Q Plastic Tube for Cable/Wire 38103573 10mm BKFN SLI

2 Mitutoyo Microscope AT112

Tektronix TDS544A Four Channel Digitizing Oscilloscope

100 Series Screw/Nut Driver

Corning 6SME Optical Cable 54761ft

NWL Capacitors 3209A 10770 Capacitor 1.67UF 90KVDC

9 Optispec Power supply/ Lamp Intesity Unit

NUGIER H25-7MD3 HYDRAULIC PRESS 25TON

NITTAN TECHNO ACM-20 CRIMPING MACHINE

NITTAN TECHNO ACM-20 CRIMPING MACHINE

FURNAS D72069-32 MAGNETIC CONTROLLER COIL SIZE 5

Meiji Techno Microscope

Dillon Weigh-Tronix Motorized DTM Tensile Test System

HP 83420A K23 AMP PAIR SOURCE TEST SET

HCS LLC 8012-50HP1 IRAM LASER APERTURE 810NM 45WATT

450 SYMBOL LA-4131 WIRELESS CARDS