Description

Key Technical Specifications

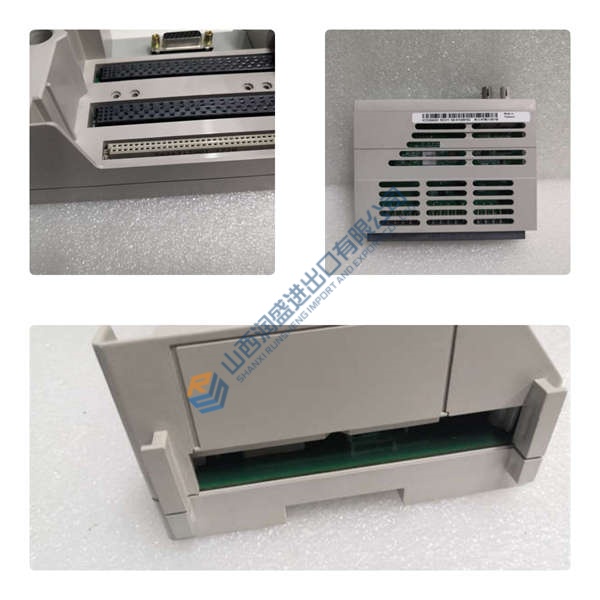

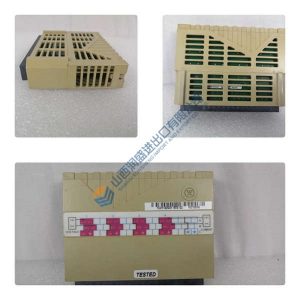

- Product Model: HDS02.1-W040N-H

- Manufacturer: Bosch Rexroth

- System Platform: DIAX04 HDS Series

- Rated Current: 40 A, supporting sustained high-power operation for demanding industrial loads.

- Peak Current: 40 A, enabling rapid acceleration without compromising system stability.

- DC Bus Voltage: 530–670 V DC, derived from regulated supply for consistent performance across varying inputs.

- Output Voltage/Frequency: 3 × 500 V AC, up to 1000 Hz, critical for high-speed spindle and servo applications.

- Power Loss: Approximately 110–125 W under rated load, influencing cabinet thermal design.

- Cooling Method: Internal air cooling with built-in blower, maintaining reliability in continuous-duty cycles.

- Continuous Current at 8 kHz: 10 A, balancing switching frequency with thermal performance.

- Operating Temperature Range: +5°C to +45°C nominal (derating to +55°C), ensuring operation in standard industrial cabinets.

- Dimensions (H x W x D): 498 mm x 50 mm x 308 mm, compact for multi-drive rack installations.

- Weight: Approximately 8 kg, facilitating handling and mounting in control enclosures.

- Protection Class: IP 10, requiring protected cabinet installation for dust and contact safety.

- Installation Altitude: Up to 1000 m without derating, higher with performance adjustment.

- Certifications: UL 508C listed, CE marked, compliant with EN standards for electromagnetic compatibility and safety.

Technical Architecture & Functional Positioning

This drive controller operates at the power amplification layer in the DIAX04 modular system, converting regulated DC bus power into precise variable-frequency outputs for a single motor axis. Its single-axis design complements dual-axis HDD modules, allowing optimized configurations where mixed axis requirements exist—reducing costs and space compared to uniform dual-axis setups. The internal blower ensures effective heat dissipation from IGBT power stages, supporting high continuous currents without external cooling aids.

Core technologies encompass pulse-width modulation with high carrier frequencies, closed-loop control supporting resolver or encoder feedback, and integrated diagnostics for overcurrent, overtemperature, and communication faults. These enable rapid response times essential for contouring accuracy in machine tools or synchronized operations in handling systems. The modular plug-in architecture permits addition of command interface cards (e.g., SERCOS or analog), enhancing flexibility for integration with various controllers.

Engineering advantages include reduced wiring through shared supply modules and robust fault isolation, minimizing downtime in critical processes. In regenerative applications, compatibility with HZB brake resistors prevents bus overvoltage during deceleration, protecting the system during high-inertia stops.

Typical Application Scenarios

- Controls main spindles in CNC machining centers, delivering precise speed regulation and high torque at low speeds for threading operations.

- Drives feed axes in printing machines, ensuring accurate registration and tension control through fast dynamic response.

- Applied in packaging equipment for servo-driven conveyors and fillers, benefiting from internal cooling in compact enclosures.

- Used in textile machinery for individual motor control in winding or weaving processes, optimizing energy use with vector control.

- Serves as replacement in legacy DIAX04 installations for robotics arms, maintaining compatibility with existing motor and feedback cabling.

Quality Standards & Testing Procedures

Drive controllers in motion systems demand rigorous verification to prevent process interruptions from subtle faults like capacitor aging or contact degradation. Our protocol aligns with Bosch Rexroth guidelines and exceeds typical refurbishment standards.

Each unit undergoes layered testing to replicate operational stresses and confirm factory-equivalent performance.

Visual Inspection & Cleaning

Assess power stages, capacitors, and connectors for wear, thermal marks, or contamination. Clean heatsinks and blower to restore airflow, verifying impeller freedom.

Tektronix 174 4363 00 174-4363-00 CABLE ASSEMBLY

COHU ER-8106A 1924999-001 REV C With Lens

Lot of 2 SONY XC-75 CCD INDUSTRIAL VISION CAMERA

Sumitomo AF-3000 AC Drive AF3002-A20-U

SYSCON INNER RACE CHECKING LINEAR TRANSDUCER

Agilent / HP 33321-60068 Step Attenuator, 0-35dB

SUPER VEXTA UDK5128N 5-PHASE DRIVER

MITUTOYO 10X /24 WIDEFIELD FOCUSING EYEPIECES 24mm

Teli CS3910 CCD INDUSTRIAL VISION CAMERA

Teli CS3730DC CCD INDUSTRIAL VISION CAMERA

SMC ZSE3-0X-21 VACUUM SWITCH VJ114 Pneumatic QTY=5

OMEGA HH506R Dual Input THERMOMETER

BECKHOFF KL2541 Stepper motor With incremental encoder

Nikon 33X / 6 Eyepieces

ORION 210A PH METER WITH COMB.PH PROBE (910600)

Parker / Daedal 402002LNMP-D2L3C5M3 travel stage

Agilent HP E3614A 0-8VDC 6A DC Power Supply

SBS TECHNOLOGIES 85224036 21-100-2 PCI HOST

GE Fanuc IC693UDR005RP1 Micro 90 PLC Controller

Acromag 983EN-4012 Ethernet Modbus TCP/IP Module

GE Fanuc IC693UDR005LP1 Micro 90 PLC Controller

Hitachi KP-F100BCL CCD CAMERA WITH 1:1.4 8mm lens