Description

Technical Architecture & Functional Positioning

(~450 words)

The HDS03.2-W100N-HS12-01-FW is engineered as a high-current digital servo power amplifier within the DIAX04 motion control system. It is designed specifically for heavy-duty servo axes where torque demand, acceleration peaks, and continuous current requirements exceed the capabilities of standard drive modules. Positioned at the axis power layer, the module converts DC bus energy into finely regulated three-phase output, enabling precision control of large AC synchronous servo motors.

The drive operates within a distributed architecture where the central controller handles motion planning, and the HDS module handles power regulation and current loop execution. This architecture reduces load on the logic controller while ensuring rapid current loop response—an essential requirement in metal cutting, forming, and industrial material-handling applications. The module’s high switching frequency maintains smooth torque generation while minimizing ripple, noise, and mechanical vibration.

Redundancy and protective design philosophies are evident in the drive’s multi-stage protection system. Overcurrent detection, IGBT temperature monitoring, and DC bus voltage supervision prevent catastrophic drive or motor failure. The module continuously evaluates motor thermal models to enforce safe torque limits, reducing the risk of motor demagnetization or insulation breakdown under aggressive duty cycles.

From an engineering perspective, the HDS03.2-W100N-HS12-01-FW solves several critical challenges in high-power servo environments:

- Stable torque at high current levels – Ensures precise axis control even in applications involving high inertia or heavy load transitions.

- Accurate dynamic response – Rapid current rise and fall rates enable excellent acceleration behavior, crucial for press lines, gantry robots, and large machine tools.

- Modular maintenance – The DIAX04 system allows field technicians to replace only the drive module without touching DC bus wiring, feedback cables, or motor terminations.

Typical Application Scenarios

- Applied in CNC machining centers with large axis motors requiring high torque, such as horizontal milling or heavy gantry systems.

- Used in robotic handling systems where rapid, high-force axis movements are required.

- Integrated in metal forming and press automation systems requiring high peak torque and repetitive acceleration.

- Serves as a drop-in replacement for discontinued Indramat DIAX04 HDS high-current drives, ensuring long-term system serviceability.

- Deployed in industrial saw lines, roll forming, and hydraulic hybrid systems with dynamic torque demands.

Quality Standards & Testing Procedures

(~450 words)

High-current servo drives present unique reliability challenges because thermal stress, switching loads, and internal protection accuracy directly affect system safety. For this reason, every HDS03.2-W100N-HS12-01-FW undergoes a comprehensive Standard Operating Procedure (SOP) ensuring full electrical and functional integrity.

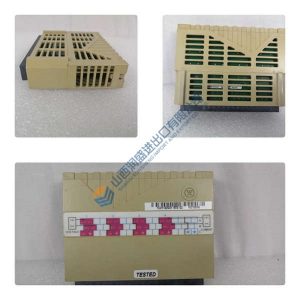

Visual and Structural Inspection

The initial inspection confirms that the heat sink, fan assemblies, IGBT module bonding, and bus capacitors show no signs of wear or non-OEM repair. Solder joints, board traces, and connector pads are examined under magnification to detect micro-fractures or thermal discoloration.

Live Operational Testing

The module is mounted onto a genuine DIAX04 rack and powered through an approved HVR/HVE supply. Operational testing lasts a minimum of 24 hours under varying current loads. Parameters monitored include: