Description

- Product Model: IS215AEPCH1B

- Manufacturer: GE

- System Platform: Mark VIe Wind Turbine Control

- Functional Designation: AEPC (Alternative Energy Pitch Center / 20 Nm ESS variant)

- Pitch System Rating: Optimized for 20 Nm torque pitch actuators with ESS integration

- Power Supply: 24 V DC nominal input from turbine distribution, with onboard regulation

- Communication Interfaces: Dual RJ-45 Ethernet ports for IONet connection to Mark VIe controller

- I/O Configuration: Supports analog and discrete signals for pitch motor control, position feedback, and status monitoring

- Operating Temperature Range: -30°C to +65°C, suitable for nacelle or hub installation

- Humidity Tolerance: 5% to 95% non-condensing, conformal coated for environmental protection

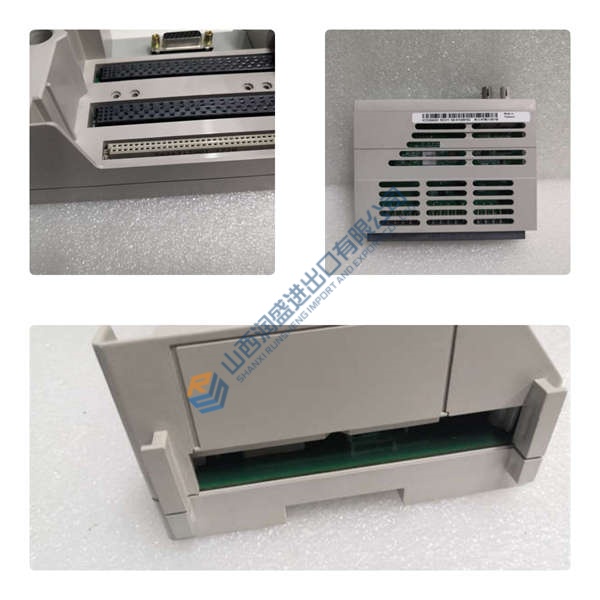

- Mounting Type: Modular card assembly with carrier for pitch cabinet or axis enclosure

- Dimensions (approx.): Standard AEPC footprint, typically 220 mm x 160 mm x 90 mm with carrier

- Weight: Approximately 2.0-2.5 kg including assembly hardware

- Protection Features: Overcurrent, overtemperature, and fault detection circuits

- Certification Standards: CE marked, compliant with IEC 61400 series for wind turbine electrical systems and EMC

- Mean Time Between Failures (MTBF): Designed for >100,000 hours in continuous renewable duty

- Response Time: <50 ms typical for pitch command processing, critical for dynamic wind response

Technical Architecture & Functional Positioning

The IS215AEPCH1B serves as the centralized pitch control hub in the Mark VIe wind turbine architecture, positioned at the pitch system layer within the hub or nacelle. It aggregates commands from the main turbine controller via IONet, distributes regulated power to individual blade pitch drives, and coordinates synchronized blade movements for optimal rotor performance. This central role enables precise collective and individual pitch control, essential for power optimization, load mitigation, and emergency stop feathering.

The module integrates power conditioning circuitry, Ethernet communication processors, and multi-channel I/O interfaces. Key technologies include redundant network paths for fault tolerance, embedded diagnostics for pitch system health monitoring, and robust signal isolation to handle electrical noise in rotating hub environments. These features directly address wind-specific engineering demands: rapid response to gusts for energy capture, reliable operation in remote locations with limited access, and integration of ESS for enhanced grid support during low-wind or fault conditions.

Its modular carrier design supports quick field swaps and facilitates expansion for different turbine variants. The architecture allows seamless diagnostics feedback to the central controller, enabling predictive maintenance and reducing unplanned downtime in large wind farms.

Typical Application Scenarios

- Implemented in GE 1.5 MW-class wind turbines for centralized pitch management, ensuring synchronized blade adjustment during variable wind speeds and directions.

- Deployed in Mark VIe-equipped onshore/offshore wind farms with ESS integration, supporting advanced grid services like frequency regulation.

- Serves as a replacement part in existing Mark VIe wind installations, maintaining compatibility with legacy pitch actuators and wiring.

- Utilized in pitch system upgrades or maintenance campaigns, improving control precision and diagnostic visibility.

- Applied in harsh environments (coastal or high-altitude sites), leveraging environmental protections for sustained reliability.

GE FANUC IC3600SSVB1 USPP IC3600SSVB1

GE FANUC IC600BF948 NSFP IC600BF948

GE Fanuc A06B-6088-H215 #H520 Alpha Spindle Drive – NEW

GE FANUC IC600BF917 NSFP IC600BF917

GE FANUC IC3600AMLG1 NSFP IC3600AMLG1

GE FANUC IC3600SSVA1 USPP IC3600SSVA1

GE FANUC TGT-3X6L-1-0-BD USPP TGT3X6L10BD

GE FANUC IC3600SLEH1G1C USPP IC3600SLEH1G1C

GE FANUC DS3800NEPA1F1E DS3800NEPA1F DS3800NEP DS3800

GE FANUC IC3600SSLA1 USPP IC3600SSLA1

GE FANUC PLC CONTROLLER 90-30

5 SLOT RACK CPU 350

GE FANUC 44A391791-G02 USPP 44A391791G02

GE FANUC IC600LX624 NSPP IC600LX624

GE FANUC IC3606SPCD1H USPP IC3606SPCD1H

GE/Fanuc IC600BF945K

GE FANUC IC3600LINB1 USPP IC3600LINB1