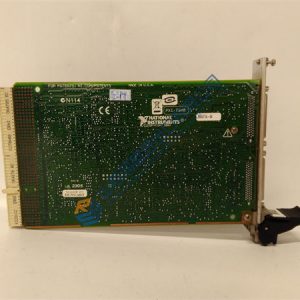

Description

- Product Model: IS215VAMBHIA

- Manufacturer: GE

- System Platform: GE Mark VIe DCS

- Input Signal Type: Voltage (0-10V), Current (4-20mA)

- Input Channels: 8

- Resolution: 16-bit

- Signal Accuracy: ±0.1% of full-scale

- Input Voltage Range: 0-10V DC

- Input Current Range: 4-20mA

- Sampling Rate: 10ms

- Isolation: Galvanic isolation between input and output

- Communication Protocol: Modbus RTU, Ethernet/IP

- Power Supply: 24V DC

- Mounting Type: DIN rail or panel mount

- Operating Temperature: -40°C to 70°C

- Storage Temperature: -40°C to 85°C

- Humidity: 5% to 95% (non-condensing)

- MTBF: 250,000 hours

- Compliance Standards: CE, UL, ATEX (hazardous locations)

- Certification: IECEx, CSA

- Dimensions: 120mm x 90mm x 45mm

Technical Architecture & Functional Positioning

Architecture Analysis

The GE IS215VAMBHIA module is a vital part of the GE Mark VIe Distributed Control System (DCS), serving as a bridge between real-world analog signals and digital control systems. Positioned in the field I/O layer, it facilitates the conversion of analog voltage and current signals from sensors, transmitters, or other field devices into digital data that the control system can process. The IS215VAMBHIA also provides galvanic isolation, which protects the system from electrical noise and ensures signal integrity in electrically noisy environments.

- System Role: This module is positioned in the analog input layer within the Mark VIe DCS, translating analog signals from various field devices (e.g., temperature sensors, pressure transducers) into digital information used by the control logic.

- Core Technology: The IS215VAMBHIA utilizes 16-bit resolution to ensure precise analog-to-digital conversion. Its high-speed sampling rate of 10ms allows real-time signal processing, making it suitable for dynamic industrial processes requiring rapid control adjustments. The galvanic isolation prevents noise and spikes from affecting the control system, ensuring reliable signal transmission over long distances.

- Engineering Value: The IS215VAMBHIA module’s ability to convert analog signals with high precision and speed ensures that processes are accurately monitored and controlled. Its galvanic isolation reduces the impact of electrical interference, providing stable and reliable operation even in environments with high electromagnetic interference (EMI). This is essential in industries such as power generation, oil and gas, and chemical manufacturing, where consistent signal processing is critical to maintaining process stability and safety.

Typical Application Scenarios

- Applied in power plants to monitor and control steam temperature, pressure, and flow in boiler systems.

- Used in oil refineries for real-time monitoring of gas and liquid flow, temperature, and pressure sensors.

- Serves in chemical plants for monitoring pH levels, chemical concentrations, and other analog variables in the production process.

- Integrates into offshore oil platforms for remote monitoring of environmental and safety parameters like gas pressure and temperature.

- Supports OEM applications for interfacing field sensors with Mark VIe control systems in custom-built automation setups.

GE FANUC 531X175SSBASM2 NSPP 531X175SSBASM2

GE FANUC IC3600AOAL1B USPP IC3600AOAL1B

GE FANUC IC3600AOAL1C USPP IC3600AOAL1C

GE FANUC IC693CPU352 IC693CPU352-BB CPU MODULE 90-30

GE Fanuc IC655MDL581A Output Module NEW Free Ship

GE Fanuc 90-70 IC697CPU771J IC697CPU771 CPU /w MEM717B

GE FANUC IC3600SVFA1 USPP IC3600SVFA1

GE FANUC SERIES SIX PLC I/O SYSTEM COMPLETE

GE FANUC A06B-0502-B074#7008 SERVO

GE FANUC A20B-1000-0940 CONNECTION UNIT *NEW*

GE FANUC ANALOG INPUT IC600YB843A 1-5VDC/4-20MA

GE Fanuc IC600LR648K Logic Memory IC600LR648-K

GE Fanuc IC600RM715K Data Storage IC600RM715-K