Description

Product Description

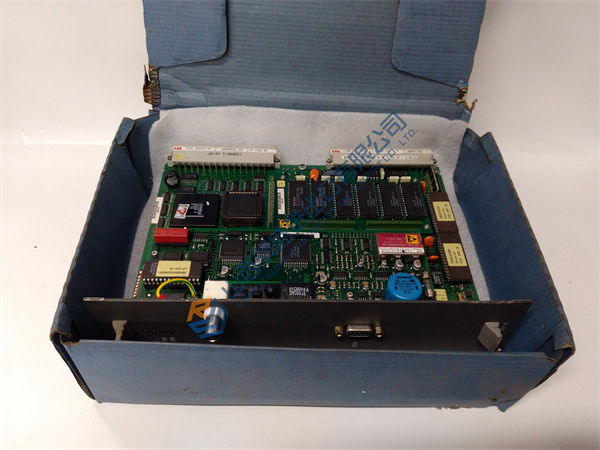

The SPU232.2 029.366.817 is a Single Processor Unit (SPU) controller module primarily manufactured by Alstom (and sometimes associated with GE – General Electric), designed for high-performance embedded control within demanding industrial environments. This robust module serves as a core processing board, capable of executing complex logic operations, managing diverse I/O signals, and facilitating reliable communication via CAN bus, making it indispensable for real-time control and automation in critical infrastructure.

Application Scenarios

Consider the complex and safety-critical operations of a modern power distribution network, where the precise control of circuit breakers and protection devices is paramount to prevent blackouts and ensure stable power supply. A major utility provider was upgrading its substations, aiming to enhance the speed and reliability of fault isolation. By integrating the SPU232.2 029.366.817 into their new protection relay systems, they achieved significant improvements. The SPU232.2 029.366.817‘s real-time processing capabilities allowed for rapid analysis of fault conditions, such as overcurrents, and immediate triggering of circuit breaker trips, minimizing the impact of disturbances on the grid. This direct application of the SPU232.2 029.366.817 addressed the critical pain points of delayed fault response and system instability, ensuring a more resilient and reliable power delivery infrastructure for millions of consumers.

Parameter

Technical Principles and Innovative Values

The SPU232.2 029.366.817 is built upon robust technical principles, offering significant innovative advantages:

- Innovation Point 1: Integrated CAN Bus for Distributed Real-time Control: The SPU232.2 029.366.817 integrates multiple high-speed CAN 2.0B interfaces (up to 1Mbps), making it ideal for distributed control systems requiring deterministic and real-time communication. This allows the controller to efficiently coordinate with other devices, such as PLCs, HMIs, and intelligent field devices, over a reliable industrial network. The CAN bus’s priority mechanism ensures critical data, like emergency braking signals, is transmitted without delay, a significant advantage over less deterministic communication protocols in safety-critical applications.

- Innovation Point 2: Flexible I/O and Logic Processing Capabilities: Beyond simple communication, the SPU232.2 029.366.817 offers a versatile array of programmable digital and analog I/Os. Its core function in performing complex logical operations (AND, OR, NOT, XOR), along with extended functions like timers and counters, enables intricate sequential and combinational control. This flexibility allows it to adapt to diverse application requirements, from controlling turnout switching in railway signaling to implementing sophisticated interlocking logic in industrial production lines, providing a versatile solution that reduces the need for multiple specialized modules.

- Innovation Point 3: Industrial-Grade Reliability with Self-Diagnosis: Designed with industrial-grade components and rigorous EMC testing, the SPU232.2 029.366.817 demonstrates high reliability and adaptability to harsh electromagnetic environments, wide temperature ranges, and vibrations. Crucially, it incorporates self-diagnosis and protection features, including real-time monitoring of I/O status, overvoltage/overcurrent protection, and a watchdog timer. These features prevent system runaway and facilitate proactive fault diagnosis, triggering alarms or safety modes in case of failures, thereby significantly enhancing system uptime and safety compared to less robust, unmonitored controllers.

Application Cases and Industry Value

In a complex automated assembly line for automotive components, the synchronization of multiple robotic arms and conveyor systems was crucial for maintaining high production rates and product quality. The existing control system was struggling with timing inaccuracies, leading to minor misalignments and increased scrap rates. By integrating the Alstom SPU232.2 029.366.817 modules at key control points, the manufacturer achieved significantly improved synchronous motion control. The module’s real-time processing and CAN bus communication capabilities allowed for precise coordination between different robotic cells and conveyor segments. This resulted in a noticeable reduction in assembly errors, an increase in overall production efficiency by 15%, and a substantial decrease in material waste. The feedback from the plant engineers highlighted the Alstom SPU232.2 029.366.817‘s contribution to enhanced process control, reduced operational costs, and improved product quality in a demanding manufacturing environment.

Installation, Maintenance, and Full-Cycle Support

The SPU232.2 029.366.817 is designed for efficient installation and robust, long-term operation within industrial control cabinets. Installation typically involves slotting the single processor board into a compatible rack or mounting it securely within a panel, followed by precise wiring of its I/O and communication interfaces. Given its critical role in real-time control, adherence to strict electrical standards, proper grounding, and effective electromagnetic shielding during installation are paramount to ensure optimal performance and minimize external interference.

Maintenance for the SPU232.2 029.366.817 is generally minimal due to its solid-state, industrial-grade design. Routine checks typically involve visual inspections to ensure secure connections and a clean operating environment. The module’s integrated self-diagnosis capabilities, including a watchdog timer and fault monitoring, significantly aid in rapid troubleshooting if an issue arises. Its modular nature allows for quick and efficient replacement, minimizing downtime in critical applications.

We offer comprehensive full-cycle support for the SPU232.2 029.366.817, encompassing expert consultation for system design and integration, detailed technical documentation, and responsive troubleshooting assistance. Our commitment includes ensuring the availability of genuine spare parts and providing expert field service to maximize the availability and efficiency of your industrial automation systems throughout their operational lifecycle.

Contact us for a customized solution that enhances your control systems with the reliability and precision of the Alstom SPU232.2 029.366.817 controller.