Description

Key Technical Specifications

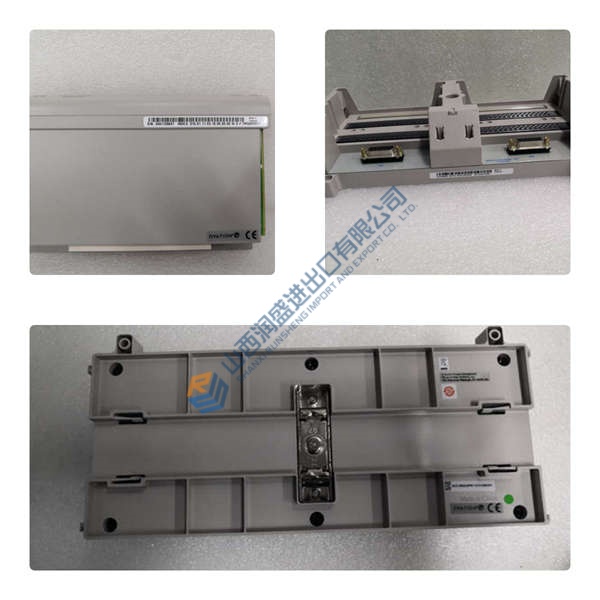

- Product Model: HDS03.2-W075N-HS12-01-FW

- Manufacturer: Bosch Rexroth

- System Platform: DIAX04 Drive System

- Part Number: R911190008

- Rated Current: 75 A

- Peak Current: Up to 75 A (short-duration, depending on duty cycle and cooling)

- DC Bus Voltage: 530 to 670 VDC

- Output Voltage: 3 x 0 to 500 VAC

- Output Frequency: 0 to 1000 Hz

- Power Consumption (Control Section): Approximately 25 W

- Cooling Method: Internal air cooling with built-in blower

- Communication Interface: SERCOS real-time optical fiber interface for deterministic motion control

- Weight: Approximately 11 kg

- Protection Class: IP10 (requires cabinet mounting)

- Operating Ambient Temperature: +5 °C to +45 °C (rated data); up to +55 °C with derating

- Installation Altitude: Up to 1000 m above sea level without derating

- Certification Standards: CE marking; cULus listed (compliance with UL 508C, EMC, and safety directives)

Technical Architecture & Functional Positioning

In the DIAX04 modular architecture, the HDS03.2-W075N-HS12-01-FW functions at the drive control layer, transforming shared DC bus power into precise three-phase AC output for high-power servo motors. Its role supports distributed processing, where motion commands arrive via the SERCOS fiber-optic ring from a central controller, enabling local execution of tight closed-loop regulation with minimal latency—essential for coordinated multi-axis systems exceeding 40 A ratings.

Advanced digital signal processing implements field-oriented control, providing exceptional torque dynamics and disturbance rejection, with current loop times supporting high-bandwidth operation. The SERCOS interface ensures noise-immune, cycle-synchronous communication (down to 1 ms), critical for applications demanding exact phase alignment, such as high-speed machining or synchronized transfer lines. The robust internal blower maintains thermal stability at 75 A continuous output, allowing denser rack populations while preventing derating in ambient conditions up to 45 °C.

This design resolves key engineering challenges in power-intensive setups: managing heat in compact cabinets, mitigating EMI through optical isolation, and facilitating scalable expansions via plug-in modules (e.g., additional I/O or encoder interfaces). It extends system longevity in legacy installations by offering drop-in compatibility with existing DIAX04 infrastructure, minimizing downtime during upgrades.

Typical Application Scenarios

- Employed in heavy-duty CNC machining centers for feed and spindle axes, handling high-inertia loads with rapid acceleration and sub-micron positioning accuracy.

- Integrated in automotive assembly lines for robotic welding or painting systems, where SERCOS synchronization ensures precise multi-axis coordination under variable payloads.

- Used as replacement in legacy DIAX04 installations during plant maintenance, maintaining compatibility with HVE supplies and existing cabling.

- Applied in metal forming presses for hydraulic replacement with direct servo control, delivering high torque at low speeds for consistent cycle performance.

- Deployed in large printing machines for drum and roller drives, leveraging deterministic communication to eliminate registration errors in high-volume production.