Description

Product Overview

The ABB PFSK162 3BSE015088R1 is a specialized control board, often referred to as a “server computer board” or “signal concentrator board,” integral to sophisticated industrial automation and control systems. As a core component within a Distributed Control System (DCS) or similar advanced control architectures, the PFSK162 3BSE015088R1 is designed to perform critical functions such as signal conditioning, data processing, and robust communication between various system components. It acts as a central hub for managing input and output signals, ensuring that data is accurately and reliably transmitted for further analysis or processing. This ABB board is engineered to meet the demanding requirements of industrial environments, delivering high reliability, stability, and efficient operation. Its role is pivotal in maintaining seamless communication and precise control across complex automation processes, contributing significantly to enhanced operational flexibility, responsiveness, and overall system performance. The PFSK162 3BSE015088R1 is a testament to ABB’s expertise in providing advanced solutions for critical infrastructure and industrial operations where precise and distributed control is essential.

Technical Specifications

Main Features and Advantages

The ABB PFSK162 3BSE015088R1 offers a range of features and advantages that make it a highly valuable component in advanced industrial control systems. Its design focuses on robust performance, flexible integration, and reliable operation in challenging environments.

Comprehensive Signal Conditioning and Processing: The primary function of the PFSK162 3BSE015088R1 is to condition and process signals, ensuring that electrical characteristics of analog signals are adjusted for accurate processing by subsequent devices. This often involves amplification, filtering, and conversion of signals to meet required specifications. For digital signals, it manages inputs and controls outputs, acting as a crucial interface for various sensors, actuators, and other control devices. This capability is vital for maintaining the integrity and precision of data throughout the automation system.

High-Speed Communication Capabilities: To facilitate fast data exchange and instruction transmission, the PFSK162 3BSE015088R1 is equipped with high-speed communication interfaces. These typically include Ethernet and serial interfaces (such as RS-232), allowing seamless communication with other control cards, host computers, and field devices. This robust communication infrastructure is essential for distributed control architectures, enabling real-time monitoring, data collection, and coordinated control across multiple nodes.

Flexible I/O Configuration: The PFSK162 3BSE015088R1 often supports a versatile array of input and output configurations, including digital inputs and outputs, and both voltage and current analog outputs. This flexibility enables it to meet diverse control requirements across different applications, controlling equipment like motors, valves, lights, and heaters. The ability to adapt to various signal types enhances its utility in complex industrial processes.

Robust Design and High Reliability: As an ABB product, the PFSK162 3BSE015088R1 is built with high-quality components and materials, undergoing stringent quality control and testing. This ensures exceptional reliability and stability, which are critical for the continuous and safe operation of industrial automation systems. Its robust construction allows it to withstand the demanding conditions typical of industrial environments.

Programmability and Expandability: The PFSK162 3BSE015088R1 typically offers flexibility for programming and configuration, allowing users to customize control logic, adjust parameters, and monitor status to meet specific application needs. Its modular design often supports expansion modules or slots, enabling the increase of input/output channels or communication capabilities to adapt to control tasks of varying scales and complexities.

Application Field

The ABB PFSK162 3BSE015088R1 control board is widely applied across various sectors requiring sophisticated industrial automation and precise process control. Its capabilities in signal conditioning, data processing, and communication make it invaluable in environments where reliable and efficient operation is critical.

In industrial manufacturing, the PFSK162 3BSE015088R1 is frequently used for automated control of production lines, such as those in automobile manufacturing, electronics production, and general assembly. It ensures precise control over machinery, conveyor systems, and robotic operations, optimizing production efficiency, improving product quality, and reducing operational costs.

For energy management systems, including those in the power generation, oil, and gas industries, the PFSK162 3BSE015088R1 is crucial for monitoring and controlling energy production, transmission, and distribution processes. It supports applications like turbine control, generator excitation systems, and substation automation, contributing to efficient energy utilization and system stability.

In the domain of process industries such as chemical plants, pulp and paper mills, and water treatment facilities, the PFSK162 3BSE015088R1 provides the necessary control for critical processes. It can manage parameters like flow rates, temperatures, pressures, and levels, ensuring process optimization and compliance with operational and environmental standards. For instance, in water treatment, it can automatically control water quality monitoring, pump operation, and dosing systems.

Furthermore, the PFSK162 3BSE015088R1 is integral to building automation systems, providing intelligent control over HVAC, lighting, security, and access control systems in large commercial or industrial complexes. Its ability to integrate with various sensors and actuators and communicate with centralized control systems makes it an efficient solution for creating smart and energy-efficient building environments. The versatility of the PFSK162 3BSE015088R1 ensures its robust performance across a diverse range of demanding industrial applications.

Related Products

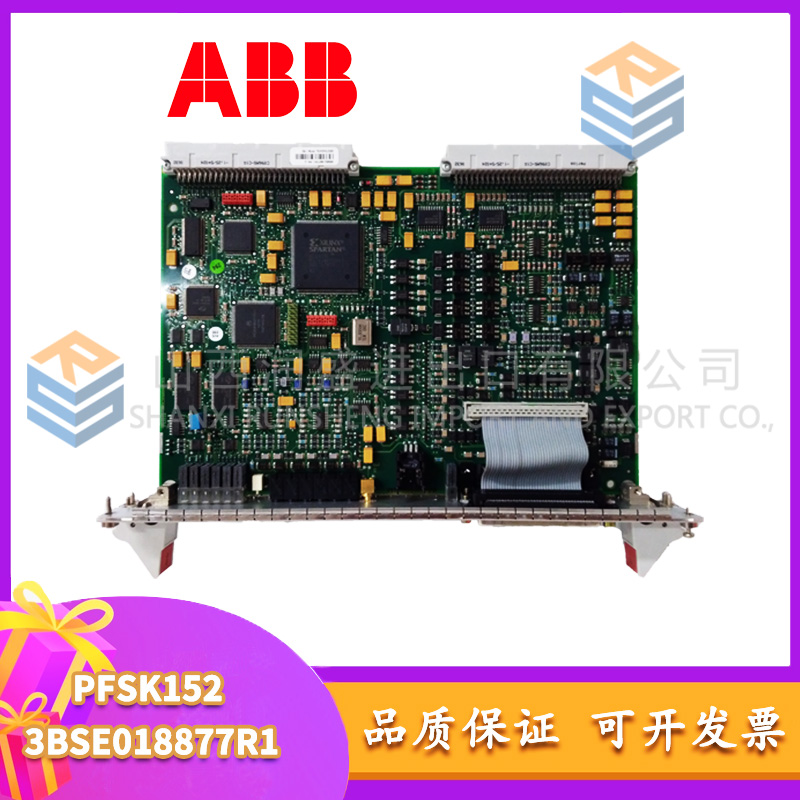

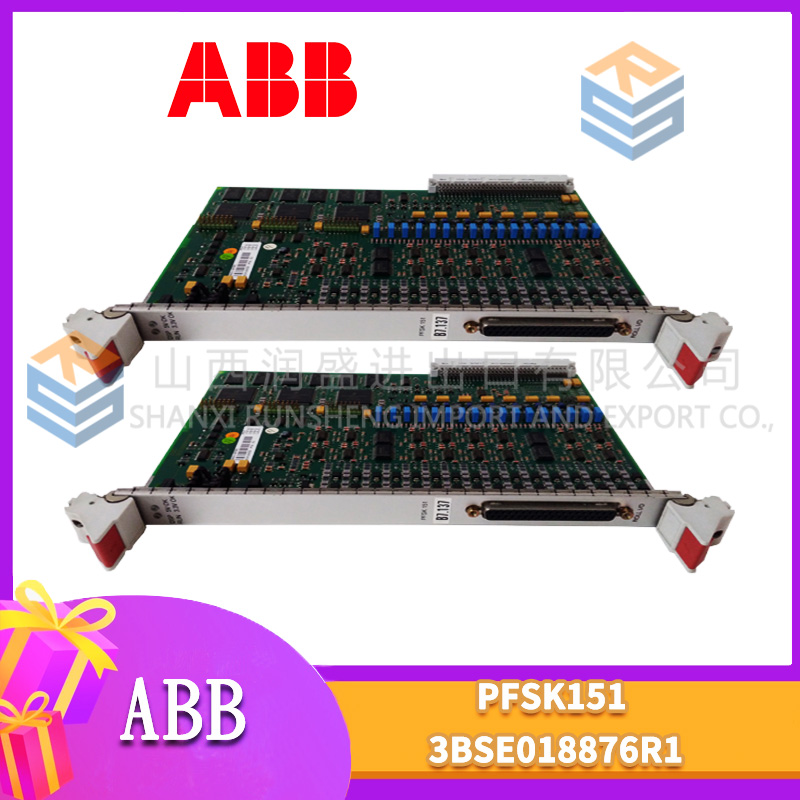

The PFSK162 3BSE015088R1 belongs to a series of control and communication boards within ABB’s automation portfolio and is often found alongside other modules from the same family or complementary systems. PFSK164 3BSE021180R1: Another control board in the PFSK series, possibly with different I/O configurations or processing capabilities, but serving a similar role in industrial control. PFSK160A 3BSE009514R1: An earlier or alternative version in the PFSK series, indicating evolution or specialization within the product line. PFSK152 3BSE018877R2: A related PFSK module, potentially an I/O module or a specialized interface card. PFSK151 3BSE018876R1: Another module from the PFSK series, likely serving a specific control or communication function. PFXA401SF 3BSE024388R4: A related module, possibly a functional extension module or a communication interface, often used in conjunction with PFSK boards. CI854 3BSE025347R1: A communication interface module, which would work alongside a control board like PFSK162 3BSE015088R1 to enable fieldbus communication (e.g., Profibus). PM866: A CPU module from the ABB AC 800M controller series, which would utilize control boards like PFSK162 3BSE015088R1 as part of its distributed I/O or specialized processing capabilities. TU810: A Termination Unit for S800 I/O, providing physical connections for I/O modules, which could be part of a system where the PFSK162 3BSE015088R1 handles higher-level control or signal conditioning.

Product Guarantee

The ABB PFSK162 3BSE015088R1 is supported by ABB’s extensive product guarantee, reflecting the company’s unwavering commitment to superior quality, reliable performance, and dedicated customer support. This guarantee typically includes a comprehensive warranty period that covers defects in materials and workmanship, ensuring the PFSK162 3BSE015088R1 performs as expected under standard operating conditions. ABB offers robust after-sales service, which encompasses technical support from experienced professionals, efficient troubleshooting assistance, and access to a global network of service engineers. This ensures that any technical inquiries or issues pertaining to the PFSK162 3BSE015088R1 are addressed promptly and effectively, minimizing potential operational disruptions. Furthermore, customers can leverage ABB’s specialized service programs, including extended warranties, preventive maintenance contracts, and training courses, all designed to maximize the lifespan and efficiency of the PFSK162 3BSE015088R1 within their industrial automation systems. This comprehensive guarantee provides customers with assurance in the durability and sustained performance of their ABB investment.